Hindcam mainly deals in three types of laser marking machines and it is categorized into CO2, fiber, and UV laser marking machines. A modern and high-tech software-embedded laser marking machine works on different processes. And, this ultimately provides fine, deformity-free, precise, and permanent marks, engrave patterns, and designs. In addition, smooth edges cut over the non-metallic and metallic surfaces. So, we shall be discussing here the different processes of the Laser Marking Machine.

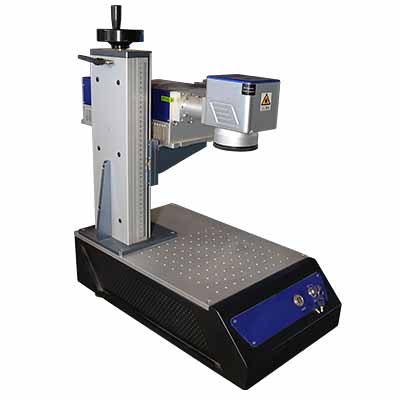

Machine’s Overview

Starting Price- Rs TBD+GST

Call or WhatsApp- 9804718718

Starting Price- Rs TBD+GST

Call or WhatsApp- 9804718718

Starting Price- Rs TBD+GST

Call or WhatsApp- 9804718718

What are the Marking Materials category?

Well, first we need to identify the marking material category of the marking machine, its power outputs, and other considerations. So, all categories of laser marking machines that is UV, fiber, and CO2 are responsible for the specified areas’ markings. Here, are some of the non-metallic and metallic materials listed for the aesthetically appealing and deformity-free marking process.

- Metals

Stainless steel, mild steel, Brass, aluminum, gold, silver, titanium, bronze, platinum, zinc, copper

- Plastics

PVC, ABS, polycarbonate, polyamide, PMMA or, plastics with laser additives

- Other materials

Rubber, wood, MDF, leather, Foils and films, Laminates, Paints, vegetables, fruits,

Different working processes of a laser marking machine

Laser marking machine (UV, Fiber, CO2 lasers) is widely accepted across the world for their different working process of marking, engraving, removing, staining, annealing, and foaming. Despite all, the core components are the focussed beam emission and an appropriate inbuilt laser tooling. So, here we shall be discussing all the working processes of the laser machine. Also read more: laser marking machine process

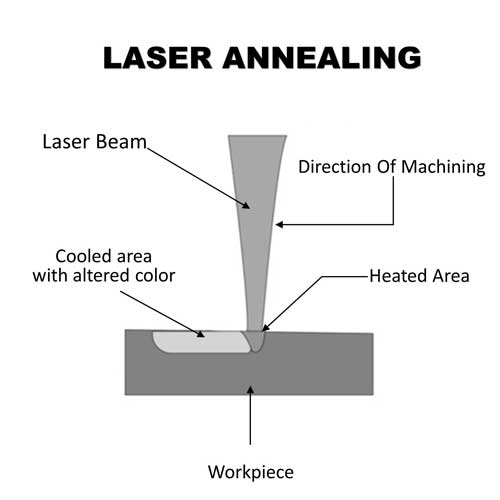

- Laser Marking by Annealing

Annealing is a process of permanent marking using high-quality laser beams over stainless steel and other metals like titanium and steel. So, we do the color markings over the metallic surfaces using yellow, blue, and brown colors. Majorly annealing is used in medical and utensils markings industries and colors have a temperature stability resistant up to 200 °C.

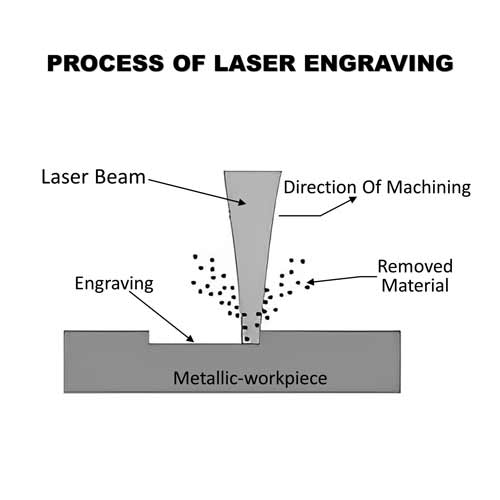

- Laser Engraving

A laser engraving process includes deep engravings over the material surfaces. By using the gaseous laser vaporization and metal surfaces melting process and with deep crevices creations procedures. In addition, Many industries need a great and appealing engraved design. Moreover, it engraves the multi-designs in woody pieces of furniture, crafts, art industries, aviation sectors, and many others.

- Laser Carbonising

Using laser technology a carbon-rich layer on the surface of a material is created. It is used in industrial applications to enhance the surface properties of certain materials. Additionally, it is also providing benefits such as increased hardness, improved wear resistance, and enhanced corrosion resistance properties of the final carbonized materials. Finally, for many industries it is beneficial in multi-application of this process including automotive, aerospace, tooling, and medical devices.

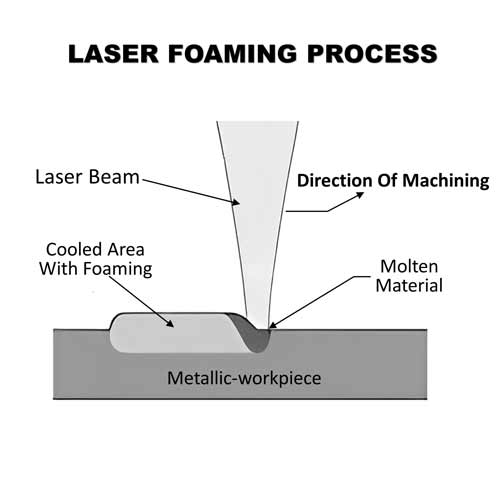

- Laser Foaming

Laser foaming refers to a process that uses laser technology to induce foaming in various materials. It involves the use of a laser beam to heat a material rapidly, causing it to expand and form a foam-like structure. Laser foaming is enhancing its presence in aerospace, automotive, electronics, and biomedical engineering. Additionly, the foaming structure over the material enhances its unique properties, such as mechanical strength, improved thermal insulation, and increased surface area. With the shown below picture, you can understand it perfectly.

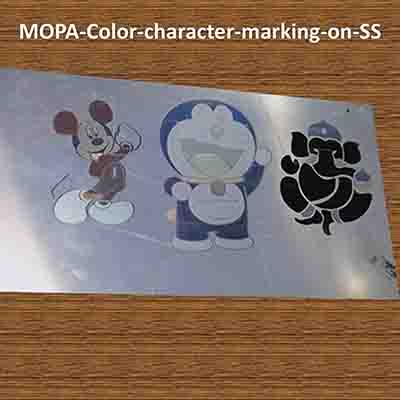

- Laser color marking

A laser color marking process is a color marking mechanism using the laser beam emission over the stainless steel using a MOPA laser technology. And, you get permanent and beautiful color marks over the metallic surfaces. So, you can enhance the products USP’s values by laser color marking. In addition, benefitting in utensils, and kitchenware industries, jewelry diversifications, outdoor and indoors, etc.

- Laser Staining

Different chemical reactions using the laser beam result in color shade creations over the material surfaces. And, the final material we get is clear and precise due to the laser staining processes.

- Laser Removing

A laser cleaning process is very important in laser techniques. It includes the removal of various contaminants from metallic or nonmetallic surfaces. Additionally, repetitive machine maintenance and materials cleaning can enhance the material’s lifespan. It includes foils and films, anodized aluminum, coated metals, or laminates and removers are paint, persistent-rust, oxide layers, etc.

Benefits of Laser Marking Processes

Although, all the laser marking processes are vast, however, there are multi-application benefits in the industry. So, here we shall be discussing the different benefits of different laser marking applications:

- It minimizes counterfeiting in many industries like pharmaceuticals, automobile, manufacturing, and packaging industries.

- It enhances product values through branding and promotional strategies using laser marking, stamping, designing, and many others.

- The marks are permanent and have a long lifespan and it gets prevented by outside environmental factors.

- The engraving and marking process is quite time and cost-efficient. laser marking machine price

- As the entire process is contactless, hence the marking quality is never compromised.

- We get clear, accurate, and precise marks and engraves within the specified marking areas.

- You can go for 2D and 3D marking processes as well to get better profitability.

Although, it has many other benefits of using all the mentioned laser processes. However, it has certain limitations as well. It includes the higher initial investment to process all the above laser processes and the material thickness has also some limitations to carry forward.

Overall, the laser marking and engraving machine has multi-applications. And thus is a highly demanding machine in the final products diversifications loophole. So, here we have gone through the entire laser marking, annealing, removing, foaming, and carbonizing process in brief. For getting more relevant information about the laser marking process, you can connect over the Call or via WhatsApp- 9804718718.