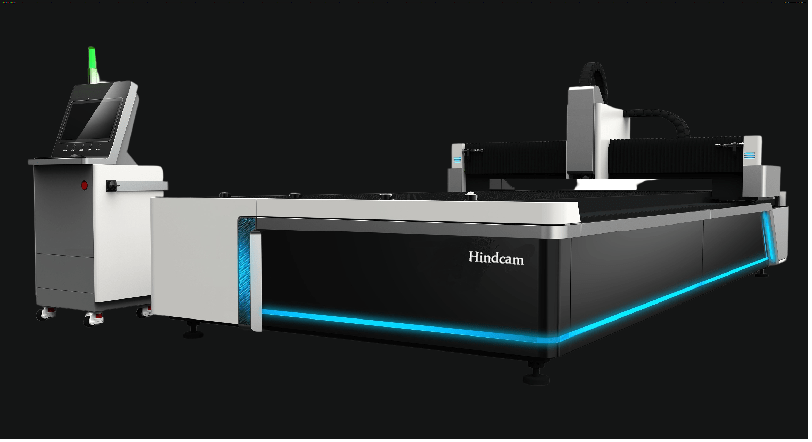

Fiber laser cutting machine is one of the most desirable machine in fabrication industry. The metal laser cutter help in increasing the production and quality of fabrication. With right kind of engineering it can also reduce scrap metal. Hindcam deals in fiber laser cutting machine. We have wide range of machine suitable for all type of need at very affordable pricing.

Product details

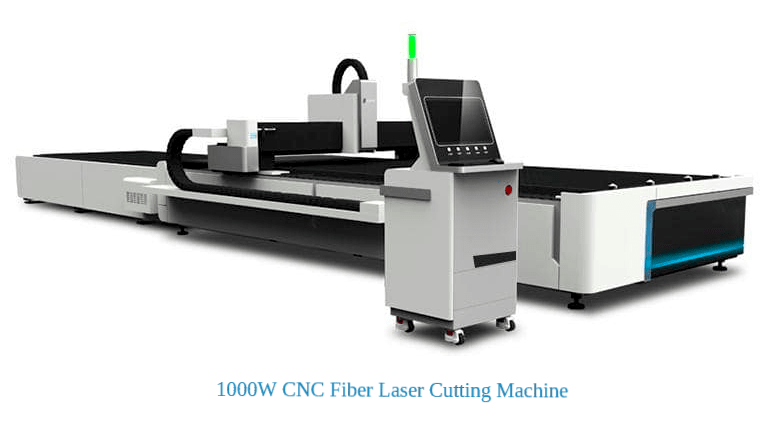

1kw sheet laser cutting machine: Usable for in house production when your need to cut only thin sheet and cutting thick sheet is not required. 1 kw want cut 10mm MS and 4 mm SS. However if you want to do job work we do not recommend 1 kw laser cutting machine as it has much lower speed at thickness over 2 mm of material.

1 kw laser cutting machine

Source: Raycus or Maxphotonics

System: Cypcut 2000 or Cypone

Servo Motors: Yashkava/Inovance or Fuji

Bed Size: 1500×3000 mm, custom size also possible

Bed: Pipe (Recommended) or Heavy Plate

Guide Rail: 30mm Taiwan Brand

Gas Controller: SMC

Water Chiller: S&A

Cutting Head: Raytool BM110

Cutting Capabilities: MS 10 mm, SS 4 mm

Starting Price: Rs 1750000 + GST

Know More: 1 kw metal laser cutting machine contact us on 9212300300

1.5 kw laser cutting machine is also recommended for in house production when cutting thickness required is less. This machine can give more clean cut at 6 mm of ms as compared to 1 kw. However speed difference is not much. Not recommended for Job work purpose.

1.5 kw laser cutting machine

Source: Raycus or Maxphotonics

System: Cypcut 2000

Servo Motors: Yashkava/Inovance or Fuji

Bed Size: 1500×3000 mm, custom size also possible

Bed: Pipe (Recommended) or Heavy Plate

Guide Rail: 30mm Taiwan Brand

Gas Controller: SMC

Water Chiller: S&A

Cutting Head: Raytool BM110 or BM111

Cutting Capabilities:

Starting Price: Rs 2000000 + GST

Know More: 1500w fiber laser cutting machine

contact us on 9212300300

2 kw laser cutting machine

Source: Raycus or Maxphotonics

System: Cypcut 2000

Servo Motors: Yashkava/Inovance or Fuji

Bed Size: 1500×3000 mm, custom size also possible

Bed: Pipe (Recommended) or Heavy Plate

Guide Rail: 30mm Taiwan Brand

Gas Controller: SMC

Water Chiller: S&A

Cutting Head: Raytool BM110 or BM111

Cutting Capabilities:

Starting Price: Rs 2250000 + GST

Know More: 2kw fiber laser cutting machine

Contact us: on 9212300300

3 kw laser cutting machine

Source: Raycus or Maxphotonics

System: Cypcut 2000 or Cypone

Servo Motors: Yashkava/Inovance or Fuji

Bed Size: 1500×3000 mm, custom size also possible

Bed: Pipe or Heavy Plate (Recommended)

Guide Rail: 30mm Taiwan Brand

Gas Controller: SMC

Cutting Head: Raytool BM111 or BM 114

Water Chiller: S&A

Cutting Capabilities:

Starting Price: Rs 2650000 + GST

Know More: 3KW-Fiber Laser Cutting Machine

Contact us: on 9212300300

4 kw laser cutting machine

Source: Raycus or Maxphotonics

System: Cypcut 2000

Servo Motors: Yashkava

Bed Size: 1500×3000 mm, custom size also possible

Bed: Heavy Plate (recommended) or Cast Iron

Guide Rail: 30mm Taiwan Brand

Gas Controller: SMC

Water Chiller: S&A

Cutting Head: Raytool BM 114

Cutting Capabilities:

Starting Price: Rs 4150000 + GST

Know More: 4kw fiber laser cutting machine

Contact us: on 9212300300

6 kw laser cutting machine

Source: Raycus (recommended) or Maxphotonics

System: Cypcut 2000 or Cypone

Servo Motors: Yashkava/Inovance or Fuji

Bed Size: 1500×3000 mm, custom size also possible

Bed: Heavy Plate or Cast Iron

Guide Rail: 30mm Taiwan Brand

Gas Controller: SMC

Cutting Head: Raytool BM 114 or BM 115

Water Chiller: S&A

Cutting Capabilities:

Starting Price: Rs 4750000 + GST

Know More: 6kw Fiber laser cutting machine

Contact us: on 9212300300

Why choose Hindcam for laser cutting machine

Hindcam provide you with cost effective and efficient laser cutting solutions. We have range and configuration of machine suitable for every need. Our machine is installed almost in every state if India. Some of salient feature of our machine are.

- High accuracy: We have highest accuracy machine in a given budget.

- Stable Bed Design: Machine bed are heat treated to make them long last.

- 2 year waranty.

- Online support

- Spare parts available all the time.

- Spare laser source available in case of Source failure

- Customization available.

How to choose a metal laser cutting machine

This brief guide shall help you decide which power you need to choose. To finalize the machine you need to consider following.

- List of materiel and thickness

- Size of Material

- Maximum thickness of materiel

If you are planning to buy the machine for your in house production machine should satisfy the above criteria. We recommend to go one level power higher than the power which meet your criteria.

If you are planning to buy laser cutting machine for job work we strongly recommend you to go for 3kw laser source or higher. The reason for this is that most of job worker in India have installed 1kw ot 1.5 kw power machine. If you have higher power machine you shall have better cutting speed. it shall give you competitive advantage over your competitors.

Accessories required with metal laser cutting machine

Gases: Laser cutting require oxygen with high purity (99.9%). Oxygen can be supplied in cylender. If you have higher requirement for Mild steel cutting you can also consider liquid Oxygen supply. Nitrogen gas can also be use for cutting Steel and other metal. Nitrogen gives clean cutting edge. Nitrogen can be supplied from nitrogen cylinder or liquid nitrogen can be used. Cost of nitrogen is higher, alternative of nitrogen is compressed air, however compressor air does not give clean cutting edge.

Air compressor: Air compressor is highly recommended to save cutting cost. If you are installing laser cutting machine for job work, air compressor shall lower your operational cost. air compressor is used in cutting thin mild steel and all other material. it is an substitute of nitrogen. Air compressor should be able to generate 15 bar air pressure at 50 to 70 cfm. Air compressor should also be equipped with air drying mechanism and air filter to remove dust and oil from compressed air.

UPS: CNC laser cutting machine is costly equipment with lot of sensitive components. UPS is necessary to keep machine running problem free. UPS also help in retaining the program and save lot of time in case of power failure.

Running cost of fiber laser cutting machine

You can watch the detailed video about laser cutting machine operating cost

Add on machinery required with metal laser cutting machine

CNC bending machine:

Laser welding machine:

Powder coating setup: