The Mopa Fiber Laser Marking Machine is better abbreviated as (Master Oscillator Power Amplifier). And its working mechanism includes an optical amplifier, which creates laser beam pulses. Its frequency ranges from 20 kHz to 1 MHz. It is best suited for metallic surfaces, such as stainless steel, gold, and many others, and helps with marking and engraving needs. It includes natural, colored, and black markings without damaging the metallic surfaces.

Specifications

- Laser Type– Fiber Laser

- Automation Grade- Automatic

- Cooling Mode- Air Cooling

- Control Software- LASER MARKING SOFTWARE

- Power- 220V AC, 50-60KHZ Volt (v)

- Marking Speed Capacity- 8000 mm/s

- Beam Deflection- Digital High Speed Scanner

- Linear Speed- 10000mm/ Sec

- Marking Area- 150 X 150 mm (Optional)

- Laser Source- JPT M7

- Software- EZCAD3

- Call/WhatsApp: 9212300300

- Available in: 50 watt mopa laser marking machine, 60 watt mopa laser marking machine

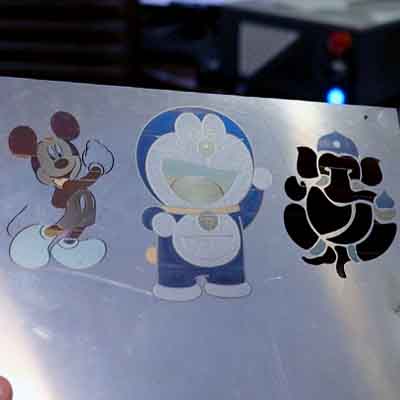

Color Marking Samples on Stainless Steel

We have collected few colored samples on the stainless steel material. Here are those shown below for better understanding.

Image-1

Best Fit materials for MOPA Laser engraving/marking

- Gold: MOPA is very useful in cutting Gold, it can be used in making customized gold jewelry by cutting gold sheets. Know more about gold laser cutting machine.

- Brass: MOPA can be used for cutting brass. It can also do some colorful marking on brass.

- Stainless Steel: MOPA can cut and Mark Stainless steel. It can do colorful markings on stainless steel.

- Titanium: It is a high-quality material and is used in multi-application at the industrial level. So, you can expect a good marking via Mopa lasers.

- Platinum: This machine can perfectly mark reflective metals.

- PLA plastic: It also marks, cuts, and anneals on PLA plastics.

- PBT plastic: Get a perfect marking and deep engraving on PBT plastic surfaces.

- ABS plastic: Laser marking machine marks and engrave over the polycarbonate and ABS material, It includes deep marking and engraving of logo, trademark, text, codes, etc.

- Silver: Silver-based ornamental design, hallmarking, and any there needs to get perfect marks engraved designs on its surfaces.

- Nickel: You can also mark the material made of nickel.

- Copper: For better marking on copper utensils or metallic markings. It is highly recommended.

- Carbide: For deep and accurate marking and engravings on the carbide surface, it is also the best-suited machine.

- Aluminum: Aluminum-based products needs very precise marks due to their reflective material nature. So, this machine can be more efficient.

- Tungsten: Mopa lasers do precise marking on Tungsten material very efficiently.

- Carbon steel: High-quality marking and engraving are one carbon steel material.

- PC plastic: You can also focus perfect marks with this machine on PC plastic materials.

- Silicon plastic: It marks over the silicon plastic materials.

Why to choose a Mopa Laser Marking Machine?

The Mopa Laser Marking Machine is durable, efficient, and is maintained well with minimal maintenance costs. You can go for fine, precise, and colored marking and engraving of metallic and non-metallic surfaces with Mopa Lasers. For industrial engraving and marking needs, it is quite effective and long-lasting. Hence, once you purchase the machine, you will benefit from its features.

Advantages

- Edges protections on metal: For the metal engravings, you will see reduced melting or scorching at their edges.

- Requires less maintainence: Less maintenance with more durability of markings.

- Reduces heat emission and improves corrosion: Metal marks cause less heat to occur, and it enriches its corrosion behavior.

- Fine and precise marking: It is well suitable for the fine marking process of metal and non-metal materials.

- Best over plastic products: The best services will benefit plastic marking, mobile phone keys, key panels, electronic components, handicraft gifts, and many others.

- Fine beam quality: MOPA laser marking has long diode life and produces the highest beam quality for precise marking and engraving of metallic and non-metallic surfaces.

- High-contrast markings: Controlled plastics melting and occasionally higher-contrast marks. With the reduced foaming.

Disadvantages

- Higher price comparatively. Mopa is an advanced laser technology. It has wide range of output pulse shapes (width, frequency and energy level). The laser source is very costly to produce. It is about twice the cost of same power Q-Switched laser source

- Two dimensional marking: The marking dimension is limited on only X and Y axis.

- Color marking is limited: MOPA colorful only marks on stainless steel. The color is removed by hard buffing as they consist of very thin layer of oxide. Color mark made using MOPA are also prone to rusting.

Features

- Mobility and compactness: The machine size takes up less space and is mobile. It is very convenient to load and replace it anywhere, as per your needs and preferences.

- Highly precise and accurate: Machines can do marking and engraving on both metallic and non-metallic surfaces with high precision and accuracy. Additionally, the fiber laser performs with the utmost precision of 0.001mm, including the diode at 0.01mm.

- Minimal maintenance costing: The Mopa laser marking system has a good lifespan and more durable, so it can be used with ease for up to 10 years. Therefore, the maintenance cost is usually zero or minimal.

- No consumables are required. The machine does not require oil, gas, grease, or any consumable to increase its working efficiency.

- Higher marking and engraving speeds: The Mopa Fiber Laser Marking and engraving machine is especially designed with high-tech software. So, you can expect higher marking and engraving speeds.

- Foot switch control: Machine has a foot switch control for repeated marking and engraving of metallic and non-metallic objects. Therefore, every time it does not require computer command. You can make the changes by pressing the foot switch.

- Upgrades in software and Simple Operation: The machine includes the latest technology to do the colored fabrication and engraving on metallic and non-metallic surfaces. It consists of software like a printer driver, graphics, CAD, and label printing software.

Applications

- MOPA laser marking machines are used in the electronic and electrical industries.

- It is widely used in the marking and engraving of mobile phones, iPads, and other electronic appliances.

- The electrical appliances include integrated circuits (IC), anode stripping, coating stripping, semiconductor.

- Stainless steel colorful marking

- Jeweler, eyewear, handicrafts products markings and engraving needs.

- PVC pipe industry marking needs.

Mopa Fiber Laser Verses UV Laser

| Mopa Laser Marking Machine | UV Laser Marking Machine | |

| Wavelength and technology | (master oscillator power amplifier), an optical amplifier used to strengthen output power. high pulse repetition via laser beam. | Ultraviolet or UV lasers : wavelength laser of 1064 nm through a non-linear crystal |

| Ideal for materials | Gold and nickel plating, Steel, Stainless steel, Brass, copper, Titanium, Aluminum , Painted materials, ABS plastic, Polyethylene, Black oxide, Anodized aluminum | Glass scribing Black annealing Polyethylene marking Silicon marking Electronic chip marking |

| Featured qualities | power, long-lasting versatility, and high-precision | highly absorptive, durable |

Mopa laser markers can be used for colored marking and engraving for industrial uses. Additionally, you can purchase the machines as per your needs and preferences. Additionally, the UV laser marking machine is also more durable and long-lasting and works on blue-beam emission technologies.

Mopa Laser Verses CO2 Laser

| Mopa Laser Marking Machine | CO2 Laser Marking Machine | |

| Wavelength and technology | (master oscillator power amplifier), an optical amplifier used to strengthen output power. high pulse repetition via laser beam. | wavelength of 10,600 nm, and uses Co2 gases tubal emersion technology. |

| Ideal for materials | Gold and nickel plating, Steel, Stainless steel, Brass, copper, Titanium, Aluminum , Painted materials, ABS plastic, Polyethylene, Black oxide, Anodized aluminum | Wood, Glass, Stone, Carboard, Paper, Rubber, Leather, Plastics |

| Featured qualities | power, long-lasting versatility, and high-precision | power efficient, Long life span |

Both Mopa Fiber Laser Marking Machine and CO2 laser marking machines are quite efficient, long lasting, and require little maintenance. Only the technology for marking and engraving is different, but it produces more precise and time and cost-efficient results. You can go for your purchases with either one of the two as per your needs and preferences.

Warranty and Services

- You get 24*7 Technical Support, VCD training video at the service station or plant.

- It comes with 19 months to 2 years of onsite warranty.

- You get proper installation as an added point with the product delivery.

- Local services are also provided.

Frequently Asked Questions

Q1. Can a Mopa laser cut metal?

Yes, it can cut the metallic surfaces like gold, platinum, aluminum etc. with high-precision and good pulse shaping controllability using the beam emission. And, check for the cutting precisions before taking a move ahead.

Q2. What is the frequency range of Mopa laser?

Mopa lasers pulse duration is 4 to 200 ns. And frequency varies between 20 kHz to 1 MHz. So, make sure you have checked up the frequency level as per your usability before the purchases.

Q3. Which material can this machine cut perfectly?

This machine is best suitable for the materials like Steel, Stainless Steel, Copper, Ceramic , plastics and many more. So, you can expect the best marking, color marking, cutting and engravings over the material surfaces via the beam technology.

Q4. What is the minimum and maximum sheet thickness that

a Mopa machine can cut?

The maximum cutting thickness is 2mm for 50 watt MOPA. Also, the thickness levels also depends on power output of the laser machine. So, you can purchase the machine as per your thickness preferences.

Q5. What is the cost of this machine?

It depends on phases, power and features you require. However it starts with (5 Lakhs plus GST for 50W of machine) and so on. So, make the price range decision and move ahead for the machine purchases as per its specification and usability.