Hindcam Pvt. Lmt is a well-renowned manufacturer of laser welding machines. A laser welding machine is used for fine, deep welding. Welding speed is 3 to 4 times higher than traditional welding. The same machine can weld many different types of metal, like SS, MM, copper, aluminum, etc. The welding pool is narrow, less finishing is required after welding, and workpiece deformation is minimal.

Laser Source and power option

The fiber laser welding machine is available with Maxphotonics laser source. Other laser source can be made available at special request. It is available in below configuration

For more details you can view individual laser welding machine page above.

Advantages of laser welding machine

- Versatility: Single welding machine can weld many type of material. It can also weld dis similar metal in many cases. Specially useful in welding hard to weld materials.

- Low distortion: The weldpool generated by laser welding machine is very narrow. Welding is done at fast speed. This reduces chances of weld distortion which is mostly caused by heat and thick weld-pool. Due to this laser welding is very useful in repair jobs for tools and dies. It is also usefull in steel fabrication.

- Fast Welding: This laser welding process is faster than other welding process. in some cases it can be 3 to 4 time faster for similar mig welding process. This save lot of cost and if machine is utilized efficiently it can cover its high investment in one year.

- Higher weld strength: Weld strength is high because the laser can penetrate deep inside the material and producing stronger joint.

- Limited heat affected zone: The welding process is fast and weld width is narrow. This help in containing heat to smaller area. and overall work metal temperature is lower than other process.

- Precision welding: Welder has more control over welding process causing precision welding

- Visible welding: As compered to other welding process. Welder can see work piece very well. So he have good control over welding process.

- High quality weld (Clean weld): The weld joint or weld pool is very small and smoother. This causes very clean and shiny weld. Which require less post weld grinding or buffing. In some cases it can be left as it is.

- Minimal post welding process: Since weld pool is small and high quality. Less buffing and grinding id required as compared to other welding process.

Watch this video

Disadvantages

- Low gap tolerance: Machine is not good for filling gaps. The parts the be weld should fit well. When fititng is good and gap is low it is the best welding process

- Higher acquisition cost: Machine is 10 to 20 times higher in cost as compared to other welding machine which can do similar work. However due to faster machine speed and better weld quality the high initial cost can be recovered quickly.

Who should buy laser welding machine

Here, you can find the laser welding machine applications in multi-industries:

- Automotive Industry: Automobile OEM are already using laser welding in many process. It is also getting popular in auto part manufacturer, because this machine can save labour cost. Many auto part manufacturer are adoping laser welding machine.

- Panel Manufacturers: Finishing is must for panel manufacturer. Laser welding machine offer faster finishing so it is becoming first choice for all type of panel manufacturers.

- Battery Manufacturers: In battery needs, a welding machine helps in better output.

- Medical components: In medical equipment, machineries and other welding needs, this machines is highly efficient.

- Sanitary Industry: All sanitization based products tools and machines gets good welding.

- Hardware Industry: electronics and hardware products like laptop, desktops, accessories and many other can be perfectly welded.

- Interior panel: you can weld the interior panel precisely using the welding machine.

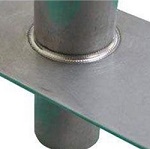

Automatic wire feeder

All laser welding machine manufactured by Hindcam are equipped with wire feeder. The wirefeeder is automatic and speed can be easily adjusted. Automatic wire feeder helps to add metal wire in weld during a welding operation. With help of automatic wire feeder we can manage the feed rate of filer wire.

We can feed the laser feed rate, weld length, and wire-to-weld ratio in machine controller. It helps to maintain constant welding surface and low heat. It also helps to fill big gaps between metals and also helps to provide higher weld strength. Feeder function can be turned off when filler metal is not required.

Feed wire for laser welding are available in mentioned material:

- Steel

- Aluminum

- Silicon bronze

Welding Gases

Welding gases used for laser welding are:

- Helium: This is best welding gas for laser welding. However it increases the cost of welding. Other gases are better option in many cases.

- Argon: Argon is costly and have some quality issues as compered to Helium.

- CO2: CO2 is cheapest but it gives poor welding quality

- Nitrogen: Nitrogen is better than CO2 and gives good weld quality. It is also one of the cheapest gas. In most cases nitrogen is favorite gas for laser welding

Welding result for different gases (Stainless Steel)

| Shield Gas | Plasma Suppression | Prevention against oxidation | Relative Cost | Flow Rate | Weld profile | Limitation |

| He | Excellent (24.5eV) | Good | High | 30-40 l/min | Deepest penetration | None |

| Ar | Low (15.7eV) | Excellent | Medium | 20-25 l/min | Wide | Plasma cloud reduces power density |

| N2 | Low (15.5eV) | Good | Low | 20-25 l/min | Deep | Embrittlement of certain alloys |

| CO2 | Low (14.4eV) | Poor | Lowest | 30-45 l/min | Nominal | Not useful for reactive materials |

| 20%He- 80% Ar | Good | Very Good | Medium | 30-35 l/min | Nominal | None |

Warranty and Services

- Tenure: You get 2 years of onsite warranty.

- Free Training: Free hands on training is available for all our customers. The training include, some welding technique, welding different types of materials, Machine care, Machine control panel.

- Customer support: You will be provided with the customer support regarding your queries.

Welding Samples

Frequently Asked Questions

Q1. What is the size of this machine?

Typical welding spot sizes varies between(50 to 900 µm) in diameter. And it has a dimension size of 98X80X94cm.

Q2. Do I need any special training to use this machine?

We assure about your product’s training and in case of any products operational queries, we will provide the necessary trainings at our service stations.

Q3. Can I weld aluminum by using this machine?

Yes, Aluminum is a reflective metal, which is handled very precisely for welding.

Q4. Can I use MIG welding wire for it?

Yes, You can use MIG welding wire.

Q5. Which welding gas will be cheaper for use?

For better and cost-effective welding needs CO2 gas is most useful.

Q6. Why it is called Fiber Laser?

This machine uses the fiber laser beam and it is combination of optical fiber doped with rare-earth elements like neodymium, yettrium etc.

Q7. Which material can this machine Weld?

Using this welding machine, you can weld the materials like: Carbon steel, Alloy steel, Stainless steel, Copper and copper alloy, Aluminum and aluminum alloy. Additionally, titanium, nickel, magnesium, refractory metals etc.

Q8. What is the minimum and maximum sheet thickness that this machine can Weld?

The maximum welding thickness rage is between 0.5 to 3 mm (0.020 to 0.118 in).

Q9. Does this machine also do cutting and cleaning?

Yes, a multi-functional fiber laser welding machine can do cutting, welding and cleaning as well.

Q10. What will be the cost of this machine?

The price ranges typically varies as listed:

- 1KW >7Lakhs+GST

- 1.5 KW > 8Lakhs+ GST

- 2 KW >9Lakhs+ GST

Q11. Can this machine weld without wire feeder?

We provide the welding machine with compatible wire feeder. However, it can also work without a wire feeder.

Q12. When is wire feeder used?

During the robotic welding, a wire feeder auto-feeds the wire and adds filler metal.

Q13. Will you give wire feeder along with it or we have to take it separately?

Our machine consists of attached complimentary wire feeder. So, you need not to purchase it separately.

Q14. Is this machine single phase or three phase?

Two wires from the single phase complete the circuit (one phase and one neutral). There are three phase wires for three-phase and a neutral wire to complete the circuit.

Q15. What is the power connection required for this machine?

It needs the power connections 1000 W to 5000 W.

Q16. How much electricity does this machine consume in a day?

A fiber laser feeder can consume 3 to 4 kWh per hour. So in a day it depends on the welding machine like from 72kwh- 97kwh electricity can be consumed during the welding operations.

Q17. What are the consumables in it?

Fiber laser welding machine includes Stick electrode, flux-cored wires, solid wires, shield gas and focal lenses and mirrors.

Q18. How long does it take to replace the consumables?

Fiber laser welding machines needs regular maintenance, and inspection. As it is more prone to get dust, gas leakages, wire feeder issues and many others. However the consumables are long-lasting and can be handled for many years.

Q19. Are consumables easily available in the market?

Fiber laser consumables includes shield gas and focal lenses and mirrors. Yes, in the market you can easily find out the consumables.

Q20. Which gas can be used in this?

Fiber laser welding machine uses the gases like He/Ne (helium and neon), Ar/Kr (argon and krypton), CO2, nitrogen.