Due to the proliferation of technology, lots of high-tech machines have entered the market for welding, cutting, engraving, and other needs on non-metallic and metallic surfaces. The handheld laser welding machine welds metallic surfaces very efficiently, non-contact-based, and then crystalizes the materials after it cools off. So, it has successfully replaced the traditional hand-held welding machine.

Using a laser welding machine, a high laser beam is passed through the metallic surfaces to fuse them and make solid joints. Further, you can expect its mass application needs in automobiles, manufacturing, aviation, electronics, and many other welding purposes.

Machine’s overview

- Laser Type- 1kw laser-welding, 1.5kw laser-welding, 2kw laser-welding

- Laser Source: Maxphotonics or Raycus

- Power Consumption: 5kw

- Material: SS, MS, Aluminum, Copper, Brass.

- Starting Price- TBD+GST

- Call/WhatsApp: 9212300300

Applications

A handheld laser welding machine is profitable for many manufacturing, construction and many other metallic products industries. So, here we will be discussing about the main applications of the handheld laser welding machine.

Automobile manufacturing Industry

The automotive industry uses laser welding machines for high-accuracy and high-speed welding of automobile parts and machinery. The mass production of automobile body components like cars, scooters, buses, trucks, and many others is required to weld precisely and damage-free. In addition, parts like chassis parts, exhaust systems, vehicle frames or fenders, wheel welding, brackets, hinges, spring seats, etc. need smooth and clean welding. Hence, you can expect perfect welding for any industrial needs in the automobile industry.

Guardrail Welding-Door and window

Using a handheld laser welding machine, you can beautifully weld over the stainless steel door and window guardrails. Also, due to the precise and damage-free welds, the surface is easy to clean and polish in the future. The high-tech laser welds come with and without a wire feeder. So, it is best over metals like aluminum, brass, copper, stainless steel, etc. for doors, windows, hinges, and any other products welding needs. Hence, with this machine, you can improve the design of your outdoor and indoor spaces.

Aerospace & Aviation Industry

The aerospace industry is a risky field, so it needs very high-strength, precise, damage-free, and top-notch welding quality. The aircraft parts have to pass the tests of flying, control surfaces, fuel tank capacity, and leak-free components. In addition, wing and body fillets and system components such as air conditioning ducts, etc. also need error-free wiring and welding to avoid any future loss of life or aerospace products.

Medical Industry

The medical industry needs many operation theatre-based medical tools and equipment with high-precision and durable welding needs. So, the medical parts manufacturing industry needs high-end handheld laser welding machines on a large scale. Medical implants, ICU instruments, and other devices that require high precision and accuracy are weld accurately using this machine.

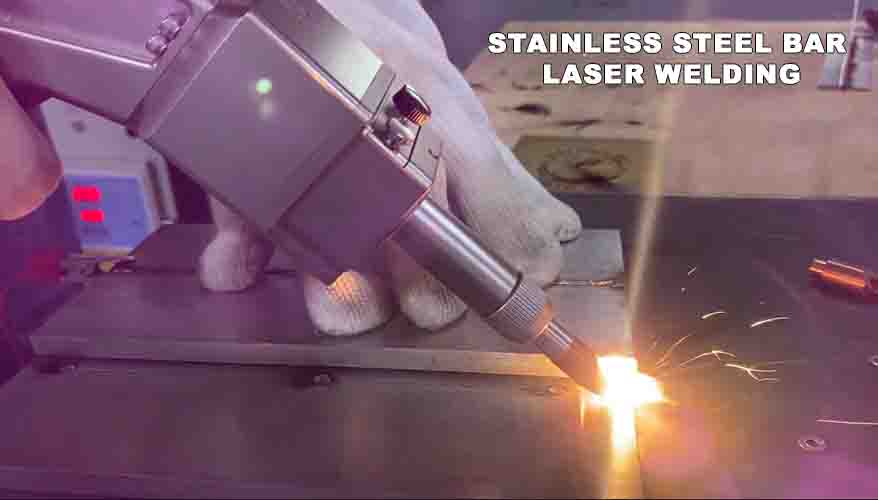

Stainless steel products

A laser welding machine can efficiently and precisely weld the stainless steel products. So, you can use the welding machine including stainless steel plate, stainless steel sheet, stainless steel tube, and stainless steel bar for effective and damages-free welding needs.

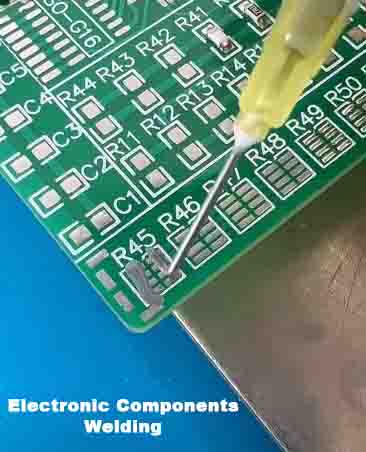

Electronics Industry

The electronics industry needs welding for products like TVs, cameras, sensors, batteries, PCBs, and many others. In the electronics industry, a high level of precision and welding quality is required to operate the products. And the final product that you get is completely durable and of higher strength.

Kitchenware industry

Kitchen utensils weldings is perfectly done using a laser welding machine such as stainless steel sinks, cabinets, range hoods, etc. Additionally, it is required for other multi-operations needs.

Jewelry Industry

Jewelry surfaces are very polished and its appearance needs to be very precise, damages free and accurate. A high-tech laser welding machine can welds over the jewelry surfaces perfectly and with the improved quality of works. And, if any parts is damaged, it can be weld to make the final finishing touch. It includes gold rings, bangles, broken pendants etc.

Summary

Finally, we can summarise here that a good welding machine is easily and smoothly operated. In addition, you can use this machine very efficiently in manufacturing, the aviation industry, kitchenware, and many other industries. Also, it can be easily operated by wearing gloves on your hands. So, it is much more convenient to use than traditional welding machines.