The handheld laser welding machine uses high-tech welding techniques with a no-contact welding process on metallic surfaces like copper, aluminum, stainless steel, etc. A laser welding machine emits high-energy laser beams over the material surfaces using the copper nozzle gun. Finally, once the surface solidifies, it leaves precise and crystal-clear welds.

Further, the laser-welded parts are deformation-free and have no welding scars. Additionally, the machine needs very little maintenance and consumables and has a long lifespan. Here, we will be discussing the working principles of a laser welding machine (1 kw, 1.5 kw, and 2 kw).

Read more : Laser Welding Machine Demo

Laser Welding Machine

A laser welding machine consists of different main components. And all are mentioned below:

Main Machine body

This combines all the components listed below

- Wire Feeder

The wire feeder uses the feeler material as per the sheet types. It is used to join the metal surfaces of aluminum, stainless steel, carbon steel, mild steel, copper etc. The laser feeder speed is 0-1000mm/min( customizable).

- Chiller

A chiller also is main component of a laser welding machine and offers high-performance refrigeration effect. It has some inbuilt features listed below:

1.Temperature stability: ±1°C, Temperature control range: 5°C ~35°C

2. It is environment friendly and consists of various alarm protection devices.

3. Using its Intelligent temperature controller, you can manage its temperature fluctuations.

- Laser Source

The laser welding machine uses better laser source quality with less energy consumption, low failure rate. The handheld laser welding machine conjoins the SS metal sheets using these laser beam sources.

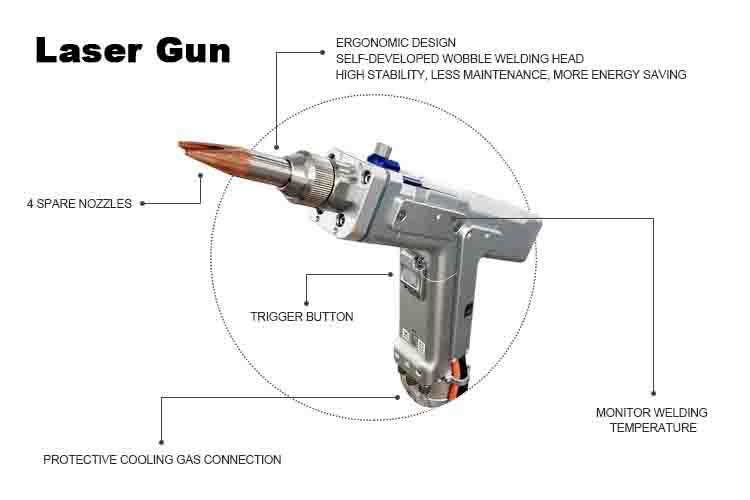

- Welding Head or laser gun:

A laser gun plays an important role in no-contact welding with the help of nozzles. A laser head emits the filler laser beam with or without the wire feeder that is telescopic and focused, and the nozzel is replaceable as per the needs of cutting, cleaning, and welding. Moreover, the welding speed is fast, precise, and within the specified area, with less heat emission in the joint areas.

Nozzel

The welding gun consists of 5 kinds of copper nozzles, which performs different functions of cutting, cleaning, welding and filling uses. The names includes filler wire nozzles, external fillet welding nozzle, flat fillet welding nozzle, internal fillet welding nozzle, cutting nozzle .

How it works?

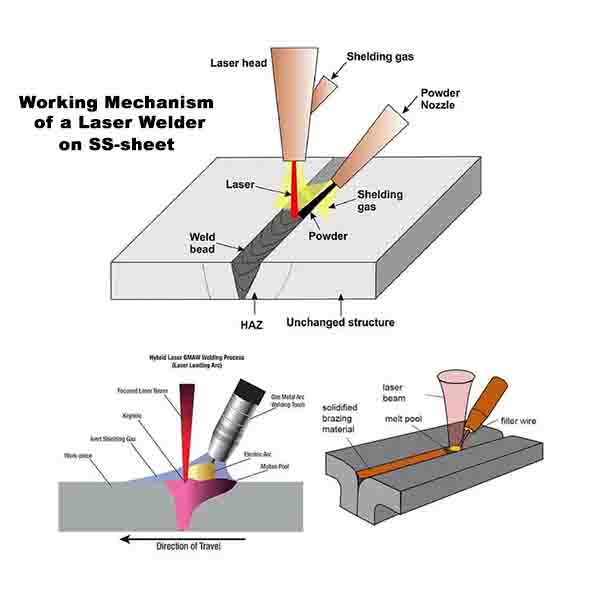

A laser welding machine works on high-energy laser beam emission technology using a wire feeder and a laser gun. If you want to cut or join MS or SS metal sheets, it is done using shielding gas (nitrogen, CO2, argon, etc.). A laser gun fills the metal surface gaps with the filler material by heating up its surfaces, and once it melts and cools off, it becomes crystalized. And, the laser source gases helps in further oxidation of the material surfaces and helps in corrosion resistance. To know more, read here: how laser welding machine works.

So, basically here, the different nozzles types are used to fill or cut the material surfaces. Finally, the products you get is free of any deformity, and easy to polish later.

Handheld laser welding verses Traditional Welding

The modern technology of a handheld laser machine consists of a wire feeder, chiller, laser guns, etc., which emit non-contact laser beams. It helps with precise welding in less time. So, there is less possibility of material surfaces being damaged, while a traditional machine takes more time and may also affect its adjacent areas due to heat emission. Additionally, laser welding is used at the industrial level in manufacturing, construction, medical equipment, and many other industries. On the other hand, traditional welding machines are not convenient, fast, easy to handle, and affect the conjoined areas.

Summary

At last, we conclude here that a handheld laser machine is durable, fast, speedy, and does precise welding, cutting, and cleaning over the material surfaces. It includes aluminum, brass, copper, stainless steel, etc. In addition, it does more accurate and damage-free welding on metallic surfaces. As well as, it is laced with high-tech welding technology and can be conveniently operated anywhere.