Colorful marking is getting famous in laser research with new technological advancements. Mopa color laser marking machine has inbuilt software laced with computer control systems like EZcad and makingmate. The colorful marking is created over the stainless steel surface by the oxidization of its first layers through a laser-induced and high-temperature process. This perfectly marks on the stainless steel products with beautiful colors and designed permanently.

What is Mopa Laser Technique?

MOPA color laser marking is the latest technology and uses laser beams for surface marking and engraving needs. It can mark beautiful colors and designs on stainless steel, titanium, gold, silver, and many other materials. It enhances the market value of final products by creating decorative multicolor effects on stainless steel.

Technical Specification

| Average Output Power | 20W – 100W |

| Laser Type | Fiber Laser |

| Linear Speed | 10000mm/ Sec |

| Marking Area | 150 X 150 mm (Optional) |

| Wavelength | 1064nm |

| Beam Deflection | Digital High Speed Scanner |

| Min Character Height | 0.2mm |

| Marking Depth | 0.04mm ( Depend on Material) |

| Power Supply | AC 220V 50Khz |

| Cooling method | Air Cooled |

| Total Weight | 280 Kg |

| Protective Cover | Yes |

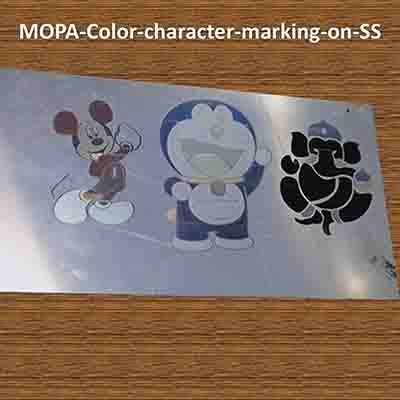

Different Color Marking Pattern on Stainless Steel

The Mopa color marking on stainless steel includes mainly five colors red, yellow, blue, green and black. And the beautiful decorative and engraving appears using its combination. The MOPA color laser marking machine adjusts the laser beam and sprays an appealing color as per the designing and specified area over the stainless steel material. Here are some of the samples of the vibrant color that a MOPA technology uses.

What is the Theory of colored marking?

As you know, the MOPA laser machine works on the wavelength range of 1064nm via laser beam emission. So, the multivariant colors(red, green, etc.) appears on the stainless steel surface. Once the light beam emits over the stainless steel material. It generates colored oxide film with laser heat sources. And the colors spay over the stainless steel due to material oxidation and the frequency of the beams.

Oxidation process

Once the required beam wavelength(1064nm) reflects over the stainless steel with the help of laser energy. Under the influence of the proper laser energy, a colorless, transparent oxide film appears on the stainless steel’s surface. The oxidation and the subsequent thin film effect creates high quality marks on the stainless steel surfaces. Moreover, the lasers functionality must have sufficient beam quality and stability to produce a precise and high quality marking. Hence the MOPA lasers are suitable in creating a permanent designs and marks with low costing via the material oxidation methods.

Other parameters

The fluctuation in power from low to high and vice-versa can steadily affect the color quality of the stainless steel material. And the color combination marks on it with the different color themes. Similarly, frequency changes also affect the beam emission quality.

Features

- Cost and time-efficient: The machine is time and cost-effective in marking and engraving needs. And reduces industrial operational costs.

- Strong and Stable laser beam Quality: The machine emits very fine and precise beam quality, which marks perfectly on the specified area over the stainless steel material.

- Ecofriendly Mechanism: The machine is environmentally friendly and does not emit pollution via harmful fumes, gases, and any other resources. So, the operator may find it quite convenient to perform any task of color marking.

- Adds vibrant colors: The machine is capable to add on the delicate and appealing permanent colors on metal surfaces. Here, you go through the major application in different industry: application-of-mopa-laser-marking-machine

- Durability: The laser machine has a long lifespan and multi-tasking with years of precise workability.

- Enhances product value: Enhances the stainless steel product’s added value due to colored marking and designs.

Advantages of Mopa Colored Marks:

- Tempering Marks: Permanent and annealing marks are created due to Less heat development on the stainless steel surfaces. And, it helps in developing better corrosion behavior.

- Creates annealing colors: More precise and vibrant multicolored designs are created on stainless steel.

- Reduced heat area: Due to the short and lower pulse energy, the specified area gets marks precisely and it also reduces the heat-affected zone.

- Higher flexibility: The machine is highly flexible over metallic surfaces for spraying the color combination, especially on stainless steel.

Disadvantages of Mopa lasers:

- Higher Investment: The machinery costing and one-time investment and set-up cost will be higher.

- Two-dimensional color marking: The color marking works only in the two-dimensional area.

Know more by watching video:

Frequently Asked Questions

Q1. How do stainless steel surfaces get distinct colors from Mopa laser marking machines?

Mopa lasers marks via chemical, and electrochemical reactions. And, it creates thin layer of the colorless transparent film on the surface of stainless steel. Further, due to oxidization films and effects of different thicknesses the different colors layers appears on the metallic surfaces.

Q2.What are the colors used for stainless steel marks?

Usually, the main color and its combinations that are used by the MOPA lasers are five colors. It includes red, green, blue, black, and yellow. And, it emits its color combinations as per the designs and colors required on the specified area.

Q3. What is passivation and is it required after laser marking stainless steel?

Passivation forms a protective layer on the surface of stainless steel with a chemical formulation. Well, due to the stainless steels self oxidation mechanism, passivation is not required. Due to its corrosive behavior, an artificial chemical layer may affect the marking quality in the future.

Q4. What is the cost of the MOPA color laser marking machine?

The MOPA fiber color marking machine price is variable. The current price for the 60W machine is now fixed at 5lakhs plus GST. However, you may connect to us for further price discussion based on specification, power consumption, and usability preferences.

Q5. Why does steel turn blue when it is heated a lot?

Stainless Steel gets self-oxidized with its spontaneous reaction with oxygen. And, once the surface is heated by the beam emission, the tempered color is created on the surfaces. Additionally, due to the oxidation process, it turns in blue with the different wavelengths of color reflection.