Hindcam offers the latest and upgraded CNC wood cutting Router Machine at the best price and specifications as per the user’s preferences. CNC wood cutting routers are used for high-end industrial and higher-accuracy cutting needs. By using this machine, we can ensure the precision of the work and the quality of the final products. It includes wood, PVC, leather, glass, acrylic, cutting, marking, and engraving all together simultaneously.

Machine’s Specifications

- Driven Motor-Stepper Motor

- Job Material-Wood, MDF, HDF, Plywood, PVC, Foam Board, Sign Board, Acrylic, Plastic

- Spindle Speed-18000 RPM

- Command Code-G Code

- Machine Type 3 Axis

- X-Y Axis Working Area-1200 x 1200 mm

- Z Axis Working Area-200 mm

- Control System DSP

- Spindle Power 1.5 kW

- Command Code G Code

- Price Rs. 350000 + GST

- Call/Whatsap: 9212300300

How it works ?

But first of all, we need to understand how a wood laser cutting machine works. Secondly, you need to interrogate the basic parameters and your overall usability preferences.

Working process: The laser cutting machine has automated software that manages all the cutting and other activities. Here, first you need to set all the parameters like material depth, cutting speed, material categories, spindle power outputs, etc. So, once everything is set, you can go ahead with the laser cutting process. Moreover, in doing so, the higher laser beam is emitted through the narrow nozzel area and cuts the marked area very perfectly. Continuing with this, it also self-manages the heat dissipation rates using its cooling management. CNC machines working Demo

The main laser cutting parameters:

- Cutting Material: We must ensure the material category for the cutting accuracy and precision works.

- Power of machines: The laser power emmission category also defines cutting accuracy.

- Spot size variability: The focus length of the focussing lens is also responsible for the better beam emmission via the cutting area.

- Cutting depth: The material cutting depth is directly propotional to cutting quality. More the depth, less will be the cutting quality and vice-versa.

How lasers are profitable in business?

If you want to start a laser cutting business but are not sure whether it will run or not, The straightforward answer is “yes” it is a highly demanding and profitable business. In addition, with the initial investments and lower maintenance rates of the machinery parts, it goes on for several years, leaving behind a great leap in the business’s growth. So here are few of the beneficial points, which you may go through before taking a move to purchase the machine:

- Multi-applications at lower costs: You will be benefitted by its multi-applications with lower costs.

- Higher accuracy level: The machine is capable to provide higher accuracy over the wood cutting, markings and overall other operational requirements.

- Material depth cutting: You get a great cutting quality with the material depth category.

- Higher demanding business: The wood cutting business is in higher demand as of now. And you can maximise your business revenue in just few years.

Overall, you can enhance the product’s brand value by tradmarking and appealing designings via cutting, designing, engravings and other needs. You can also calaculate the laser cutting cost.

Pros and Cons of laser cutting machines

Although every new laser technology is very helpful for higher productivity and faster processes. However, we can’t deny its cons as well. So, here are some of the pros and cons of the machine:

| Pros | Cons | |

| 1. | Higher-cutting accuracy | Limited material thickness |

| 2. | Multi-applications. Like aviation, the furniture industry, toys, etc. | Higher-initial-investments |

| 3. | Enhances the product’s values and brand awareness. | Limited to up to a certain material categories |

| 4. | Great business expansion via planning and implementation | Increases unemployment |

| 5. | Highly automated software support for multiple applications | Needs software upgrades with changing technologies |

| 6. | Reduces material waste via streamlined cutting processes | Outdated tools will be hard find out |

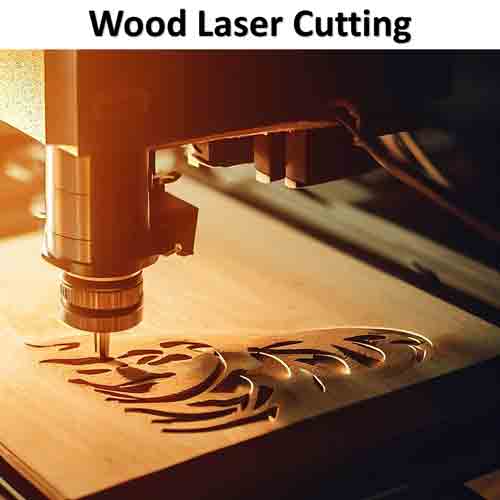

Work Samples: Wood Laser Cutting

Here are some of the wood laser cutting samples from a 1.5 kW spindle wood laser cutting machine:

Other related article to read:

Frequently Asked Questions

Q1. What are the materials to be cut using a wood laser cutting machine?

Answer: A CNC laser cutting machine does perfect cutting over non-metallic materials like wood, acrylic, glass, MDF, leather, etc. In addition, a few categories of metallic materials can also be cut using this machine, i.e., aluminum, brass, etc.

Q2. What is the market’s best price for a 1.5 KW spindle-power laser cutting machine?

Answer: Although the price difference depends on the spindle and power output category, However, you can also get better cutting accuracy using a 1.5 kW spindle. And the current best buy price of the laser cutting machine is Rs. 350000+GST. Further, get better clarity over the prices and specifications by calling or messaging 9212300300.

Q3. What is the cutting speed and accuracy level of the wood laser cutting machine?

Answer: A wood laser cutting machine has great accuracy and cutting speed to do industrial cuttings over woody products and others.