A laser welding machine is used for error-free and precise welding using nozzle beam emission technology. Many industries have opted for welding machines because of their cost and time-efficient working methods. And, using this machine, all kinds of materials, including reflective materials and metallic surfaces, are welded damage-free, deformity-free, and with easy maintenance. So, here we will get an idea of the benefits of using high-tech laser welding machines.

About Machine

Benefits

There are many benefits to using a handheld laser welding machine, and here we will be discussing the main 20 benefits of its non-stop operations:

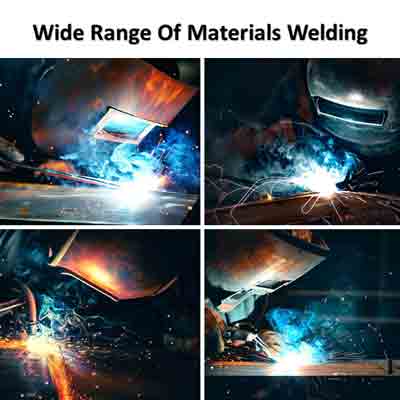

1. Welding done over a wide range of materials

With the welding lasers, different metallic and non-metallic materials with different thicknesses can be precisely welded. It is widely used in medical tools, the construction industry, the automobile industry, the jewelry industry, and other similar industries. It includes copper, titanium, steel, stainless steel, aluminum, plastics, textiles, etc. In addition, the welding quality is of higher quality and deformity-free.

2. Non-contact welding

The entire welding process is non-contact-based, and using the laser gun, which emits the laser beams with or without the type of wire feeder. So, the material surfaces go through the heating and melting process over their surfaces, and later on, the final oxidation using the shielding gases (nitrogen, argon, etc.). Moreover, you can initiate the welding process by wearing only gloves and goggles for better protection.

3. Multi-functionality

Using the laser beam sources, the welding machines perform multi-functions such as cutting, cleaning, heat treatment, marking welding, and many others using the modified nozzle. As well, it is very versatile over the different metallic and non-metallic surfaces that need welding and other treatments.

4. Non-stop operations

The welding machine can efficiently work for many hours or non-stop operations. And the work output that you get is of higher quality. For any type of welding, you can use the perfect machine outputs like 1 kw, 1.5 kw, and 2 kw.

5. High-precise welding

For high-precision welding needs, it is highly recommended. And the welded material will be long-lasting and easy to police and clean. Additionally, you can easily notice the precision of the work throughout the welding materials.

6. High-quality weld

The laser welding quality and the joints are sharp, clean, durable, and of high quality. The final product, which you can see, is smoother and requires less post-weld grinding. Further, many industries can expect great welding quality over jewelry surfaces, SS sheets, utensils, kitchenware, indoor and outdoor units, etc.

7. Low Distortion and heat output

Laser welding machines, during their welding operations, cause low distortions over the material surfaces and affect adjacent areas with low heating. It protects the material’s smooth surfaces from any deformity. So, you can expect better accuracy within the welding areas.

8. Low maintenance costs

Machines need minimal maintenance due to their perfect mechanical lifespan and arrangements. Also, the operator finds it easy to use and handle during welding, cleaning, and any other needs.

9. Compact and portable Machine

The machine looks very compact. In addition, it is a portable machine, and each component can be perfectly placed and carried from one place to another without any damage to the surfaces.

10. Higher-efficiency

The welding machine can work very efficiently for many hours non-stop. And, it is approximately about up to 2000 meters/per day (8 h).

11. Perfect cooling systems

The machine has a chiller system, that perfectly manages its temperature and controls the temperature fluctuations. So, you can manage its working operations without any fear of heating issues during its non-stop operations.

12. Safer operations

The welding machine is safe to use, and anyone can operate it by maintaining a perfect distance using gloves and a goggle to save from heat and light emissions. So, you can entirely rely on its safe operations.

13. Higher-Beam Quality

The beam quality of the welding machine is high. It includes beams based on fiber and CO2 lasers, like gases, mixtures, fiber beams, etc. So, you can expect better beam emission and final welding quality.

14. Deep and narrow welds

Due to the higher aspect ratio, the weld is deep, narrow, concise, and accurate. In addition, in keyhole laser welding the weld materials are of greater depth.

15. Inbuild Automated process

Laser welding has an inbuilt automated process. And, it is made for multi-axis robotic systems for welding, cleaning, marking, and cutting needs.

16. Less wastage

The laser welding machine has less waste during multi-operations. So, once you compare its functionality with the traditional machines, you will find it is easy to maintain and leaves less residual material due to damage-free welding, cutting, and other works.

17. Less labor costs

As this machine is automated, it is easily managed using the machine’s buttons. Therefore, it requires minimal labor costs, and hence the production of the final products will be precise and require fewer labor costs. Hence, the final operating costs are minimal.

18. Time and cost-efficient machine

Compared to traditional machines, this one-time investment in handheld welding machines brings fruitful results. And, you finish up the multi-tasking in less time and money costing.

19. High-tech laser welding software

The multi-operations become significantly more powerful because of its built-in professional laser welding software. It can therefore perform high-speed, precise welding operations.

20. Environment-friendly

The welding machine is emitting less fumes and gasses, and also it has better cooling systems. Therefore the entire operation is quite environmental-friendly. And, the operators’ health will also get less affected due to the prolonged emission of fumes and harmful gasses.

Reasons for welding machines’ popularity

- Laser Welding machines are widely used for industrial uses and it is operated very efficiently.

- The beam quality and beam emission are very precise and accurate, so it is very demanding for large-scale industrial operations like jewelry, aviation, etc.

- It gives time- and money-efficient welds, and the material surfaces are free from any deformity or heated areas.

Summary

At last, after finalizing all the points, you may get a clear picture of the benefits of using a handheld welding machine for a long period of time. And you may entirely depend on its durability, high-tech software, and multi-operational tasks. Further, the machine is very time- and cost-efficient compared to traditional welding machines.