Hindcam deals in laser welding machines that can be handheld welding machines and TIG(Argon welder). Laser welding works are required everywhere where two metallic surfaces need permanent joints through neat and clean welding. Here, we need high-tech laser welding machines with a handgun and wire/without wire feeders. So, here we will discuss about the core deferences between Laser Welding and a Argon Welding machine.

Handheld Laser Welding Machine

A handheld welding machine works on the focused beam emmission using a handgun and copper nozzels. This includes a precise cutting over the stainless steel, copper sheets, iron sheet, galvanized sheet and many more. In addition, the machine includes a welding machine, a chiller for cooling managements, a wire feeder and a handgun.

Samples of handheld laser machine

Argon Welding

Argon welding, also known as tungsten inert gas (TIG) welding or gas tungsten arc welding (GTAW). It uses the electric arc between a tungsten electrode and the metal piece durng its operations. The shielding gas used, are argon, CO2, oxygen, helium and many others.

Argon welding works precisely over the metals, including stainless steel, aluminum, copper, and titanium. And, you get a high-quality welds with minimal spatter and excellent weld appearance. This process is commonly used in industries such as automotive, aerospace, and manufacturing, where precise and clean welds are essential.

| Welding Type | TIG Welding |

| Voltage | 220-440 V |

| Output Current Range | 100-400 A |

| Automation Grade | Semi-Automatic |

| Frequency | 50-60 Hz |

| Phase | Three Phase |

Arc welding work and samples

Comparison- Laser Welding vs Argon Welding

| Laser Welding | Argon Welding | |

| Beam technology used | laser to create a weld(fiber beams) | electric arc to create a weld(inert tungsten gas) |

| Material thickness | less thickness | thicker material |

| Feaured qualities | quicker, great precision work | versatility and convenience |

| Affordability | more expensive than argon welding | less expensive |

| Best materials | stainless steel,mild steel,aluminum alloy etc. | stainless steel, aluminum, copper, and titanium. |

| Laser Welding Application | Automobile Tool construction Steel construction Shipbuilding Fine jewelry | welding and casting industries, |

| Welds appearances | Slight golden | slight blue |

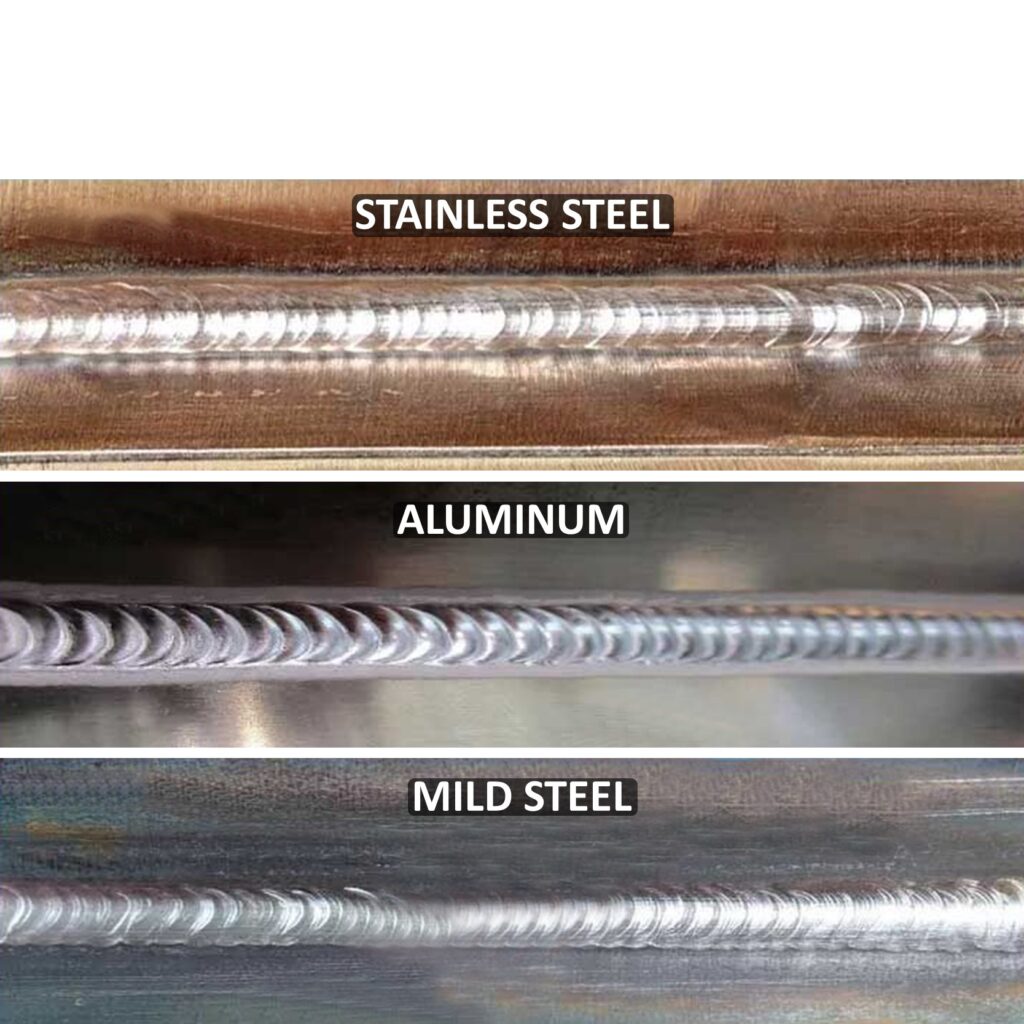

Sample comparison – Laser Welding vs Argon(TIG) Welding

Here are a few of the samples, which you find different due to laser beam technology. So, here you can see the welding differences on the SS sheet as the laser welding machine color is slightly golden, whereas the color of the Argon is slightly blueish in nature. However, the quality of precision and welds are permanent and durable, So, both technologies are enough to bring fruitful welding quality.

Which technology is the best laser or TIG?

Now, comparing both the technology of laser and TIG, you will find the laser beam emission technology is much better. It includes the many factors that define its precise and high-beam quality advantages over the argon gasses technology. So, here are a few of the points which could differentiate both of them together.

- More accurate and precise weld quality: Laser welding enables higher accuracy and clear welds over the metallic materials, that would be free of any deformity. On the other hand, TIG uses the electrode for welding operations that may need tool changes and can erode, wear or even get damaged over time.

- Faster processing time: The laser welding machine has high-tech inbuilt software which makes the entire operation very smooth and increases its processing time. However, it is not a similar case in the TIG machines.

- Lower heat input: The laser welding machine has lower heat input and consequently makes the heat-affected zone smaller. Whereas, it affects the welding area more in the argon machine.

- Finished edges quality: Laser fiber technology can be very efficiently and the edges welding will be fine and perfect. However, inert gas shielding requires refinishing on the material edges after the welding work is done.

- Complex gaps gets filled up: A high-quality laser beam can efficiently fill the materials complex gaps. Whereas this case is not silmilar in the TIG electrode.

Read more:

At last, we can conclude that going for the laser beam technology can be initially more costly. However, you can get reliability, better efficiency, and better welding quality. In addition, purchasing a machine as per your usability and requirement can perfectly define the TIG/ laser machines. To know more about the product’s specificaion and services, you may connect @Call or WhatsApp: 9804718718.