Hindcam Pvt Lmt deals in fiber laser marking machine that does gold and silver ornamental precise marking and designing. The machine’s high-tech software helps in product marking, i.e. serial marking, date sampling, barcodes, hallmarking, product identification, etc. Our Jewelry Laser Marking Machine saves time and money through its automatic operations.

Machine’s Overview

- Laser Type-Fiber Laser

- Laser Power- 20W, 30W,50W,60W,100W

- Marking Depth-0.1 TO 0.5

- Marking Speed Capacity- 7000 mm/s

- Usage/Application-Gold & silver marking

- Laser Wavelength-1064 nm

- Automation Grade- Automatic

- Voltage-230V

- Frequency- 50Hz

- Starting price-Rs.TBD+GST

- Call or WhatsApp: 9310620946

Key Features- Gold Laser Marking Machine

- Automatic Operating System: A gold laser marking system consists of EZCAD software. And it is the necessary operating tools that manages the marking, designing, and other operations.

- Marking speed is higher: Equipped with digital technology for high marking speed.

- Higher scanning speed: It has Galvo-laser head, which has a great inbuilt scanner and it performs very efficiently.

- Minimal maintenance costs: The machine does not require any consumables and has low processing and maintenance costs. This makes productivity faster comparatively.

- Air-cooled machine: It has a streamlined cooling process inbuilt to manage the heat and laser beam’s heat fluctuations during the running operations.

- No Consumables Required: It does not need inks, oil, and any other consumables for operations, so it reduces further maintenance costs.

- Long-lifespan: It has a longer lifespan of 100,000 hours.

Why Gold laser markers are globally accepted?

The jewelry industry is the fastest-changing industry across the globe, that follows the consistent flow of trends. A laser marking machine is in demand in various industries, including the jewelry industry. When it comes to gold jewelry, laser marking machines offer precise and permanent engraving. Moreover, it allows you to create intricate designs, hallmarks, logos, or identification marks on gold jewelry pieces. Here are some key points for laser marking machine globalization for gold jewelry markings, cuttings, and designing needs:

- Laser Technology: Laser marking machines utilize laser technology to engrave or mark the surface of gold jewelry. The laser beam interacts with the gold, creating a controlled heat reaction that vaporizes the material and leaves a permanent mark.

- Precision and Detail: Laser marking machines provide exceptional precision and detail, enabling you to engrave intricate designs or inscriptions on gold jewelry without damaging the piece. This is particularly important for delicate and valuable jewelry items.

- Non-Contact Process: Laser marking is a non-contact process, which means the jewelry piece remains untouched during the engraving process. This reduces the risk of damage or deformation, ensuring the jewelry’s quality remains intact.

- Versatility: Laser marking machines offer versatility in terms of design possibilities. You can mark logos, serial numbers, barcodes, decorative patterns, or personalized messages on gold jewelry. The laser EZCAD software allows you to create and import designs easily using simple computer controls and settings.

Although, you get precise and accurate markings over the gold smooth surfaces. However, it’s also essential to consider the specific requirements and settings before any marking operations. In addition, the jewelry industry has certain rules and regulations regarding jewelry markings, such as hallmarking standards or quality control guidelines.

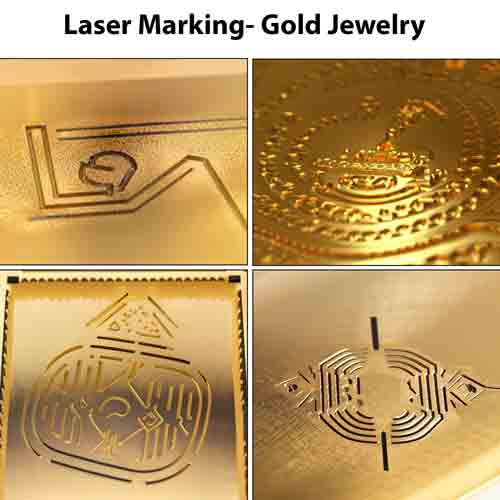

Samples of Laser marking

Benefits of Laser Marking over Gold Jewelries

A gold laser marking machine is very beneficial in terms of brand awareness and visibility. Also, it is required to do the hallmarking over the trendy pieces of jewelry. As all the jewelry designings are trendy, so every time designing is created using computer controls and easily marked via the fiber laser beam emissions. So, here we will be discussing the benefits of laser marking using laser machines:

- Intricate and detailed designs: A fiber laser marking machine has inbuilt software and computer controls. So, you can easily modify the intricate designs with a few settings and mark them within the specified areas over the ornament’s smooth surfaces anywhere needed.

- Very-precise marks and engravings: A fiber laser marking machine can mark, engrave and design very precisely and with a higher accuracy level over Gold and silver bangles, necklaces, rings, etc.

- Reduces material wastage: Similarly, once you compare the material wastage with the traditional machine. Here, the wastages are very minimal(0.1% approximately), so this ultimately reduces the making costs and increases the revenue.

- Mass-production: The jewelry markings are helpful in large-scale productions. So this helps in the mass-productions of jewelry marking, designing, and engraving needs in minimal time..

- Non-contact process: The entire laser marking process is non-contact based, so the quality of the mark will not suffer.

How to do hallmarking on Gold jewelry using lasers?

Nowadays, a hallmarking business is necessary for the approved sale of gold, silver, platinum, and diamond jewelry. This distinguishes the jewelry and prevents the final products from counterfeiting. Customers are also more likely to trust a product with a hallmark. Therefore, starting a hallmarking firm might be a wise and successful decision. But how can a laser marking device stamp the jewelry with precise hallmarking?

Now, this could be better understood here. To label a product more, rotary tools on a laser machine are now placed over the worksheet. In addition, with the proper laser setup using all the parameters, including power, speed, and frequency, are adjusted based on the type of gold and the desired marking depth.

An operator can create the marking items and their sizes on the computer panel when the fitting pieces are finished. Additionally, you must use scanners to adjust the Galvo head placement and the Ftheta lens. In the end, after all the work is done, beautiful hallmarks are created on the material surfaces. This shows the purity of Gold, year of marking, logo, etc.

Overall, Laser hallmarking offers several advantages over traditional methods, such as hand stamping or mechanical engraving. It provides high precision, finer detail, and the ability to engrave complex designs accurately. Laser engraving is also a non-contact process, minimizing the risk of damaging delicate jewelry pieces. Moreover, it is a fully-automatic machine, making it suitable for large-scale production more suitable.

Frequently Asked Questions

Q1. Is the laser marking machine’s efficiency affected by the material depth of Gold?

Answer: Yes, the thicker gold sheet markings and engraving will not be as good as the less-depth materials. However, you can go for the better machine’s power output above 50W for better efficacy.

Q2. What is the price of a Gold laser marking machine?

Answer: The gold laser marking machines’ price is Rs TBD +GST. To Know More connect us at call/WhatsApp: 9212300300.