A CNC wood carving machine is performing multi-operational works using the focussed beam emissions. And, it includes marking, engraving, carving, cutting, and intricate designing over the material surfaces. In addition, the machine has high-quality, high-speed scanning and carving speed that can be utilized flawlessly in multi-industries. Further, it best fits over the materials like wood, acrylic, leather, and many other non-metallic materials and a few metals category.

Machine’s Overview

- Machine Type- CNC wood carving

- X-Y Axis Working Area-1300 x 2500 mm

- Spindle Power- 3.5 kW

- Maximum Cutting Speed-30 m/min

- Spindle Head Type-Single Spindle

- Spindle Speed-24000rpm

- X-Y Movement-Rack & Pinion Transmission

- Z Movement-Ball Screw Transmission

- Command Code-G Codeu00.mmg.plt

- Driven Motor-Stepper Motor

- Job Material-Plastic, Wood, Acrylic

- Price Rs. 350000 + GST

- Call/Whatsap: 9212300300

How is a CNC wood carving machine perfect over conventional machines?

The CNC wood carving machines have high-tech tools and machinery with upgraded software computer commands. It is used in multi-tasking and leaves intricate designs via carving and engraving patterns. In addition, you can expect the higher-precision works with its 3.5kw of spindles performances. Further, the best material carvings can be seen over plastics, wood, foam, PVC, MDF, stone, acrylic, glass, ACM, copper, brass, aluminum, and the list continues. The major advantages of using the automated-carving machines are as follows:

- Less-wastages: Compared to the conventional machines, you will see great differences in less material wastage during the intricate carving operations.

- 3-dimensional carving effects: By using high-end machines, the intricate and complex 3-dimensional designings looks very realistic and appealing.

- Time-saver: The machine is very time-efficient and can do multi-tasking in a limited time, so it is very beneficial in small, mid, or large-scale carving industries.

- Higher-lifespan: Although, the initial investments are higher to invest. But the machine can run for many years.

- Less-maintenance: The machine does not require any consumables and needs very minimal maintenance compared to conventional. And, ultimately this reduces the further investment due to reparable parts.

- Infused tools: It has automated operations with the infused tools and parts, that participate in different operations.

Advantages of using a CNC laser machine

Once the uses of high-tech CNC laser machines have been introduced into industrialization. It has enhanced the marking usability preferences with a few automated settings. It includes depth controls, material choices, speed, and many other parameters. So, here are some of the advantages of a CNC craving laser machines:

- Consumes less energy: This machine works very efficiently in multi-industry and saves energy with its time-efficient work and no consumables.

- No Prototype Required: Automated software is capable enough for any automated designing, so it reduces the prototyping costs.

- Safety considerations: An operator feels totally secure during its running operations. As everything is fully automated.

- Fast production: A CNC machine delivers faster production and fulfills the consumer’s high demands in a minimal timeframe.

Disadvantages

- More costly: The CNC machines generally come into a costlier frame, so it is a bit confusing about their initial investments. Get to know more about cnc machine price.

- Introduced unemployments: The modern CNC machines do not need laborers, operators, or helpers compared to the conventional ones. So, it has led to much unemployment in a loophole.

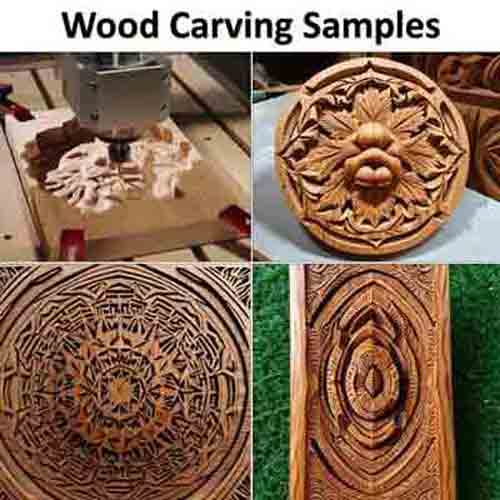

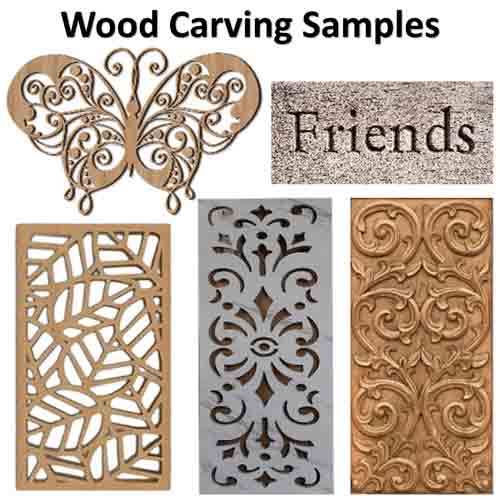

Wood Carving Works

Here are few of the samples of the wood carving using a laser carving machine.

Frequently Asked Questions

Q1.Which material categories(wood) are the best for CNC carving?

Answer: A CNC carving machine is the best over the woody material. And, it includes Beech, Oak, Walnut, Cedar, etc. In addition, materials like MDF boards, Plywood, and Particleboards.

2. What are the CNC 3D CARVING best woody materials?

Answer: For 3D carving, less tearable woods are most recommended. So, you can go for Cherry, Maple, and Redwood.

Q3. What is the best price for a CNC wood carving machine?

Answer: The best buy price is Rs 350000+GST. However, connect us for further clarifications at Call/Whatsapp: 9212300300.