Laser marking machines are required to permanently mark, engrave, and anneal on metallic and non-metallic surfaces using the beam technology. The lasers use different beam emission technology, so they are categorized differently. Fiber lasers (fiber beam), Co2 lasers (Co2 gas tubal emission), UV lasers (UV beams), and Mopa lasers (beam pulses) are all examples of lasers. It includes aluminum, stainless steel, copper, plastics, wood, ceramics, stones, and many more.

Specifications: Co2 Laser

A CO₂ laser marking machine is best suitable for the laser marking/ engraving over non-metal materials. It includes materials like wood, acrylic, leather, glass, plastic, and ceramics. It can provide high-precise, and permanent markings on surfaces up to 5mm thickness for the non-metallic materials. Common applications include branding, barcodes, serial numbers, and many others.

| Laser Power | 20 W |

| Laser Type | Metal Tube |

| Laser Cooling | Air Cooled |

| Laser Wavelength | 10.6 μm |

| Pulse Repetition Rate | ≤ 20 KHz |

| Marking Range | 60×60 mm ~ 300×300 mm |

| Linear Speed | ≤ 7000 mm/s |

| Laser Source Expected Life | 45,000 hours |

| Min. Character Size | 0.20 mm |

| Minimum Line Width | 0.05 mm |

| Repeatability | ±0.01 mm |

| Power Consumption | 800 W |

| Electricity Requirements | 220V/50Hz/3.5A |

| System | Laser, Scanners, Power Source, Controls Electronics and Computer built into laser System |

| User Interface | Touch Screen Display / PC with Wondows 10 OS |

| Connectivity | USB Port for file and configuration transfer |

| Environment Conditions | 15 degree C (59 degree F) to 40 degree C (104 degree F) external temperature / Humidity < 95% without condensation / Vibrations Free Area |

| supported Graphic format | .plt,.dxf,.bmp,.pcw,.dxf,.cdr |

| Rotary Device | Optional |

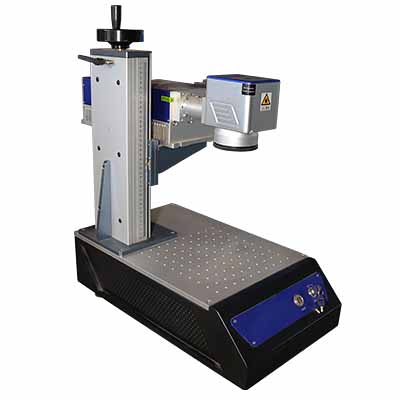

Specifications: Fiber lasers

A fiber laser marking machine can laser mark/ engrave over the numerous metallic material. It includes stainless steel, aluminum, titanium, copper, and some plastics. It delivers high-precision, permanent markings on surfaces up to 10mm thick. Ideal for engraving barcodes, logos, and serial numbers, it’s widely used in aerospace, automotive, and electronics industries.

| Power | 20 W to 100 W |

| Wavelength | 1063 ±3 nm |

| Beam quality | <1.2 (M2) |

| Output power adjustment range | 10 – 100 % |

| Pulse repetition rate | 20 – 400 KHz |

| Power stability | <±1% |

| Focus spot diameter | <0.05mm |

| Working area | 70 X 70/100 X100/150 X 150/200 X 200/300 X 300 mm |

| Max marking depth | 1.2mm |

| Max marking speed | 1500 standard characters / second |

| Minimum line width | 0.05mm |

| Minimum character | 0.5mm |

| Repetition accuracy | ±0.003 mm |

| Operation system | Windows XP /7/8/10 |

| Cooling mode | Air cooling |

| Ambient temperature | 15°C – 35° C |

| Power requirement | 220V/single phase/50Hz/<600W |

| Life of laser module | 100000Hrs |

| Guide Laser/Red Aiming Beam | Yes 660nm |

Specifications: UV lasers

A UV laser marking machine provides marking/engaving upto 3mm of thickness. It is best suitable over the materials like is glass, plastics, ceramics, PCB boards, and many others. The best industrial usability of marking/engraving includes logos, and serial numbers in electronics, pharmaceuticals, and high-tech industries.

| Max Laser Power | 3W/ 5W |

| Laser Wavelength | 355 nm |

| Repetitive Rate | 20 KHz – 150 KHz |

| Marking Range | 100 x 100 mm ~ 300 x 300 mm |

| Linear Speed | ≤ 7000 mm/s |

| Min. Character | 0.20 mm |

| Minimum Linear Width | 0.05 mm |

| Repeatability | ±0.01 mm |

| Power Consumption | 500 W |

| Electricity Requirements | 220V / 50Hz |

Specifications: Mopa Lasers

A MOPA laser marking machine performs high-precison laser marking upto the thickness of 5mm. It is ideal for metals like stainless steel, aluminum, titanium, and some plastics. Major applications include electronics, automotive, and jewelry industries for branding, serial numbers, and complex designing.

| Laser Type | MOPA Laser |

| Usage/Application | PCB Making |

| Marking Area | 300×300 mm |

| Marking Depth | 3mm |

| Capacity | 6000 mm/s |

| Supporting Format | PLT |

| Automation Grade | Automatic |

| Voltage | 220V |

Best Fit Material

- Steel.

- Stainless Steel.

- nickels

- Leather

- Cloth

- Acrylic

- Polyester Resin

- Titanium.

- Aluminum.

- Copper.

- Ceramic.

- Plastic.

- Glass.

- PVC

- allium, arsenic, phosphorus, indium

How Does Laser Marking Work?

- Laser marking: Laser marking machines works on generating focused beams of light that contain high levels of energy. Once the laser beam hits metallic or non-metallic surfaces, it creates the designs as directed by the computer commands. The marks can be colored or black and white. Similarly, the laser marking machines do the below work:

- Laser engraving: Through this technique, beams can deeply put permanent marks over the metallic and non-metallic surfaces that can resist wear, tear, and friction.

- Laser etching: It creates high-contrast permanent marks over the material via the beam emissions at a high speed.

Benefits

- High-precision marking: It provides exceptionally high processing speeds and perfect marking.

- Cost & time efficient: A laser marker helps in mass production of complex marking, designing work in cost and time-efficient ways.

- Low power consumption: Irrespective of the laser marking material needs, it consumes comparatively less power consumption.

- Highly resistive laser marking: The permanent markings are highly resistant to acid, abrasion, and heat.

- Less Marking time: It is usually between 1~3 second over any compatible materials.

Application in Industries

- Electronics hardware tools

- Electrical instrument appliances, like switchboards, cables, etc.

- Aviation and spaceflight appliance markings and engravings

- Jewelry hallmarking

- Garments like shirts, jeans markings for logo designs, etc.

- Gifts and accessories marking

- Office devices and furniture marking.

- Sanitary ware appliance;

- Dishware and Kitchen appliances

- Food and beverages industries.

- Drinking, smoking, and alcohol packaging and markings.

Pros

- the laser machine can mark any material (metallic and nonmetallic)

- Any surface is easily marked whether it is curved, plain surfaces

- Lasers give permanent marks.

- Eco-friendly technology.

- High-speed marking is very time-efficient.

- High-resolution and high-contrast markings

- Markings readability is neat and clean.

- No consumables are required for machine performance and maintenance.

- The overall marking process is No-contact based and with low maintenance.

Cons

- The high initial investment to marking needs.

- Different laser beam technology is required for markings on different materials.

- Marking is performed only in two dimensions.

- It lacks marks on materials that have a high hardness or a low ignition point.

How to choose best laser marking machine?

Before moving ahead to choosing which marking machine is best fit for you. Here are the few points which you should look into consideration:

- Type of Identifier: For the marking needs on QR codes, 2D codes, data matrix codes, alphanumerical serial numbers, graphics, or logos, you must choose the best-fit technology for beam emissions.

- Readability Rate & Permanence: The marking machines work fine on the reading performances of barcodes or scanners. As well as the permanence also affects the machine’s performance.

- Durability and compactness: The machine has to be durable and compact so that it occupies less space and all the parts are durable.

- Available Marking & Cycle Time: You must analyze the available marking cycle time during its operations.

For Example:

Fiber lasers use ytterbium to generate photons. It has a 1,064 nm wavelength, thus it is ideal to mark metals.

CO2 lasers use a CO2 mixture via tubal emission. It has a wavelength range between (9,000 nm and 11,000 nm), thus being fit for organic materials.

Watch the video

Get better clarity over the laser marking machine by watching on these related videos.