Laser CNC cutting machines and plasma cutting machines both use high-tech and automated techniques of laser beam emission over the material surfaces. However, many major comparisons are in the loop, that differentiate both the technology. Although, both are required for industrial applications in construction, manufacturing, aviation sectors, and many more. So, here we will be discussing all the possible differences between both technologies.

1. Laser Cutting Machines

For, industrial cutting applications, mainly it has two types of laser cutting CNC machines. It includes a Fiber laser cutting machine (for metallic materials cutting) and CO2(non-metallic material cuttings). So, here for better, precise, and automated cutting, these laser cutting machines are used. Further, the focused laser beams passes via the material surface on SS sheets to cut it thoroughly on different sizes and thickness levels. It includes aluminum, copper, zinc, stainless steel, acrylic, plastics, MDF, etc.

- Fiber-laser-cutting-machine

- CO2-laser-cutting-machine

- Starting price- TBD +GST

- Call or whatsapp: 9804718718

Working phenomenon

A laser cutting machine uses beams of aligned photons over the material surfaces at a specific wavelength. And, the beam emission is based on gas tubal emission(CO2, nitrogen, helium, etc.) or fiber-based beam emission. In addition, the beam emission melts and vaporizes the metal surfaces and starts the precise cutting over the specified area. Further, all the cutting works are done up to the destined cutting thickness and working command through the automated CNC machine.

Advantages of using a laser cutting machine

- High-tech software: A Laser CNC machine has updated high-tech inbuilt software that controls all the cutting commands.

- High-cutting accuracy: A machine uses beam emission technology, that helps in precise and accurate cutting using the computer command.

- Lower maintenance: A laser machine requires less maintenance.

- Higher cutting speed: It has a faster cutting speed, over metallic or non-metallic surfaces.

- Lower operating costs: As the machine has computer-operated commands, it reduces operational costs.

- Finished edges: You can expect the finished edges using CO2 lasers and fiber laser machines.

Best fit materials for Laser cutter

- Wood: A CO2 laser cutting machine can cut precisely over woody products.

- Paper: Industries can do the paper cutting work using the cutting machine.

- Plastics: Also all kind of cutting, engraving and other operation over the plastics-related with this machine.

- Aluminum: Aluminum comes under reflective materials, so you can also expect perfection in its cutting thickness.

- Stainless steel: SS- metal sheet cutting precision

- Marble: All marble product cutting and designing are done with this machine.

- Stone: For cutting different kinds of stones, this laser machine works.

- Tiles: For shaping and designing works over tiles.

- Glass: For the glass material cutting accurately without any deformity.

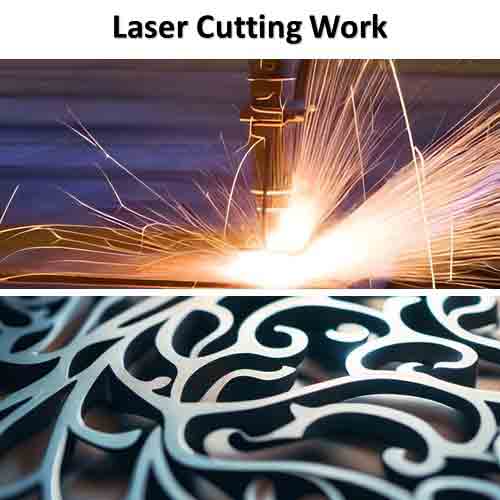

Samples of laser cutting

2. Plasma Cutting Machine

A plasma cutting machine is used for the cutting accuracy on conductive materials like stainless steel, copper, Carbon steel, aluminum, cast iron, and other metal materials. Additionly, it includes the metal cutting thickness of (2 mm and higher) to upto cutting holes (smaller than 6 mm in diameter). Further, it perfectly cuts the SS-sheet, aluminum plates, and other materials and also designs using the CNC software command.

Working phenomenon

Plasma cutting technology is mostly used over conductive material, and it is done through the electrical arc stuck between a cathode and anode. Now, the superheated (up to 20,000°C) inert gases are passed through the electric arc over the metal surfaces for cutting. Further, here we will go through the advantages of it with the points listed below:

Plasma cutting machine advantages:

- Low initial investment: low investment price (up to 5 times lower price in comparison to laser)

- low operating cost: Due to its inbuilt software, it needs less operating costs.

- Material thicknesses: It can cut thicker metal SS sheets, MS sheets, aluminum, copper, cast iron, etc.

- Cutting accuracy: The plasma cutter machine provides higher cutting accuracy over thick metal.

Best fit materials for plasma cutter

- Copper: A plasma cutter can cut up to 2mm cuttings thickness over the copper sheets.

- Silver: Silver ornaments a be cut perfectly using a plasma cutter.

- Aluminum: A plasma cutter can cut up to 160 mm of aluminum sheet.

- Graphite: It can also smoothly cut over graphite materials.

- Steel: all kinds of steel products cutting done with a plasma cutter.

- Gold: You can expect precise cutting up to 1/2″ on the gold surfaces.

- Iron: You can also cut these conductive materials accurately using a plasma cutter.

- Platinum: Platinum ornaments or material cutting and designing are done using this machine.

- Mercury: Mercury material is cut precisely with this machine.

- Bronze/brass: Trophies, utensils, and other materials are done using the machine.

- Carbon nanotube: You can also cut this material.

- Zinc: The plasma gas beam emission can cu the surfaces deformity free.

- Tungsten: You can also enhance your cutting preferences using a plasma cutter over the tungsten materials.

- Graphene: Cutting thickness is 1.2 nm on SiO2/Si surface.

Samples of Plasma cutting

Fiber laser cutting verses Plasma cutting

| Fiber laser cutting | Plasma cutting | |

| Working Principle | It works on high-quality laser beam emission technology over the metallic or non-metallic surfaces. Later the vaporized metal surface is removed from the slit using high-pressure gas. | Electrically charged forced gases(inert gasses like argon or nitrogen ) passed through a small nozzle over the conductive materials. |

| Best Fit Material | Metallic(aluminum, copper, stainless steel, etc.) and non-metallic materials(MDF, plastic, acrylic etc.). | Conductive materials (stainless steel, Carbon steel, aluminum, copper, cast iron and other metal materials) |

| Cutting thickness | Medium thick plate( 0.08mm – 1mm ) | Medium thin plate, steel cutting up to (150 mm (6 in) |

| Cutting accuracy | faster, more accurate, (within 0.2mm) | Rough machining (within 1mm) |

| Slit width | Very small (0.2 ~ 0.3mm) | Small |

| Heat affected zone | minimal (width 0.1mm) | Small |

| Plate deformation | minimal | Small |

| Applications | jeweler, constructions, aviation etc. | manufacturing, construction industry, fabrication shops, etc. |

| Work environment | Clean, less smoky | Smoke filled the house |

Advantages-(Plasma Cutting vs Laser)

- Costing preferences: Plasma cutters are economical compared to laser cutters.

- Thicker Plates: Plasma cutters can cut thicker plates (up to 38 mm). And, laser cutters have some limitations regarding material thickness. I.e. 19 mm for stainless steel,

- Minimal Maintenance: A plasma cutting machine requires less maintenance than a high-tech laser cutting machine.

Disadvantages- (Plasma Cutting vs Laser)

- Kerf size: It has a larger kerf size and provides less cutting accuracy.

- Harmful Radiation emission: The plasma cutter emits harmful radiation, and due to this the operator needs to wear protective items like helmets, goggles, etc.

- Best over Conductive Materials: A plasma cutting machine can give precise cutting over only the conductive materials. In addition, it includes Copper, graphite, carbon steel, etc.

Which cutting machine is most beneficial?

If you are confused about the laser cutting machine and its usability preferences. You can first analyze and set your cutting’s thickness, material type, budget preferences, and other parameters. However, both laser machine provides great cutting accuracy on different material types.

Summary

Finally, here we have discussed the major differences between a Fiber laser cutting machine and a plasma cutting machine. And, perfectly got an idea of its cutting accuracy, material thickness limitation, precautions to use the machine, and other parameters. Furthermore, for industrial application uses and as per the usability preference anyone could perfectly decide on which machine will perform well over the different materials category. For more queries @Call or WhatsApp: 9804718718