A laser cutting head plays an important role in laser beam focusing over the cutting materials. It enhances the laser cutting quality with high-precision beam via the the focusing lens and its adjustments with the current depth and focal length. However, here we need to understand about all kind of parameters that needs to be aligned properly to get the high-precision cutting quality.

In metal cutting and fabrication industry a laser cutting machine has been a great performer over the cutting proficiency for any kind of highly-reflective metal like aluminum, brass, ss, ms and so on.

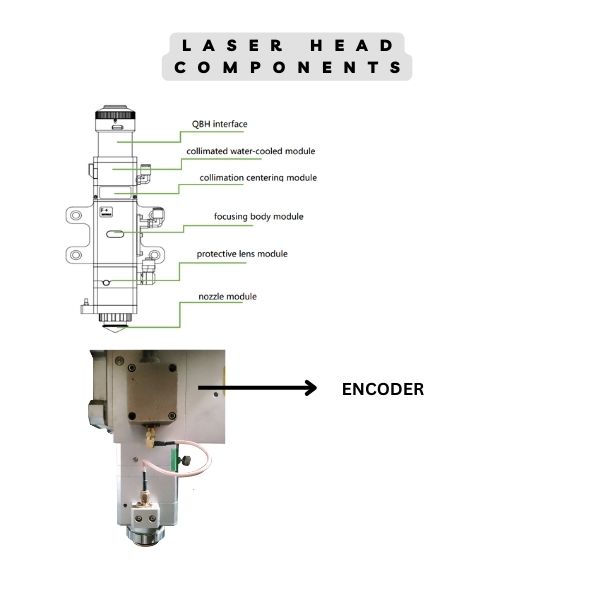

Laser head is the source of laser beam used in all laser motion and position measurement system. Laser head is one of the most important part of the machine. Fiber Laser heads are extremely light weighted. It contains three protractors, one colimating lens and one focusing lens. With fiber laser head the metal cutting process is contactless, so the cutting quality is also very good. It is used for high precision metal cutting.

How to install a laser cutting head?

In laser head, laser beam of conical shape from fiber laser source enters through the fiber optic path cable. After which it passes through the colimating lens where the laser beam converts into cylindrical shape. Laser beam of cylindrical shape is preferred for laser cutting because it produces a perfect round shaped beam which is necessary for precised cutting. After colimating lens the laser beam passes through the focusing lens. Focussing lens is used to focus the laser beam on or in the material as programmed. After these process focused laser beam comes in contact with auxiliary gas (i.e high pressure air, nitrogen or oxygen). Auxiliary gas is used to increase the heat an pressure of laser, which makes cutting fast and easy.

A water cooling system is also attached in laser head which is used to protect it from the heat which occurs in it during laser cutting. Cause of very high temperature generated during laser cutting the lenses in laser head can damage. So water from chillar circulates in the laser head, which keeps the internal temperature of head constant without effecting the cutting process.

Here are some of the easy installation steps of the laser cutting head:

1 . Gas circuit: Set up assist gas supply and adjust settings.

2. Water circuit: BM111 has two water cooled channel connection. A water-cooled interface for a laser cutting head dissipated heat generation and ensures the safe workflow.

3. laser beam centric mechanism: Here, we need to connect the beam delivery system to the head. And, we have to properly align the nozzle, focusing lens, and mirrors with the appropriate focus length.

| Laser head Mode | BM111 |

| CL/mm | 100 |

| FL/mm | 155 |

| H/mm | 417.8 |

| Automatic focusing range | + 10 ~ -12mm |

| adjustment accuracy | 0.05mm |

| Maximum acceleration | 10m / s2 |

| Weight/KG | 6.3 |

| fiber interfaces | QBH, QD |

4 . Mounting holes: Before mounting of the laser head, we should do a proper grounding. After that we do the proper mounting of the laser cutting head onto the machine’s Z-axis.

Top functions of a laser cutting head

A laser cutting head is the main component of the laser cutting machine that manages all the activities of motion sensors, beams integrations and high-precision cutting.

Here are some of the major functions of laser cutting machine head:

- Focused beam delivery: A beam delivery system of the laser cutting head focuses precisely over the cutting material. And, a correct focal length is adjustable as per the material cutting thickness.

- Material cutting height controls: The attached motor sensors helps in height adjustment as per the cutting thickness, designs and the cutting material. So a correct height adjustments improves the cutting quality.

- Feature of anti-collision: Raytool laser cutting head is laced with anti collision features. And, it automatically adjust the nozzles and beam delivery as per the material and work-piece orientation.

- Controlled assist gas system: Due to its controlled assist gas delivery system, gases like the oxygen, nitrogen, or compressed air. All these can be controlled with the setting of gas pressure and required flow rate.

- Cutting-edge performance: We can expect high-precision and consist cutting all over the cutting material. Whether it is a highly reflective metal surface, the cutting quality over its edges and corners are done at the same proportion. So, this reduces the possibilities of material damages and scraps ratio.

- CNC system compatibility: The laser head has an easy access to all commands with the CNC based systems. So, this enhances the optimal cutting performances.

Read More

How to service a laser cutting head?

A laser cutting head is the most essential component that participates in high-precision cutting of numerous materials. However, it needs a repeated cleaning, maintenance and servicing for optimal performance and to ensure high-quality cuts.

So, we can follow step-by-step process for servicing a laser cutting head:

1. By powering off the machine.

We should always power off the machine properly to perform the servicing activities, as this relaxes all its components, which could eventually help in its highest working performance.

2. Cleaning of the Lens

A lens fets dirty after repeated operational activities during laser cutting jobs. So, it is mandatory to clean and service the lenses to completely remove dust, debris, smoke, and other particles from their surfaces. For this we can use the soft cloth and cleaning solutions effectively. We also need to immediately replace the lens in case of any scratches, cracks, wear, tear or burns.

3. Cleaning Nozzle

We must repeatedly inspect the laser head nozzles for any damage, wear, and tear and replace them accordingly. We usually use three types of nozzles with different lengths and depth controls. It includes single layer, double layered and copper nozzles. medium-diameter nozzles (1.5-2.5 mm) to large (2.5-4.0 mm). We must check for the assist gas passages and nozzles cleaning via a cotton swab.

4. Checking and Replacing Filters

The cutting head consists of air and assist gas filters. And it needs regular cleaning activities with its operational activities. So, we must check, clean or replace these filters regularly. This finally delivers high-precision laser cutting via the assist gas and clear air passages.

6. Inspect Gas Lines and Connections

We need to do a periodic checks of the gas lines for any further leaks, cracks, or blockages. In case of any damages this can block the gas flow to the laser head and can lead to poor cutting performance.

8. Alignment control & Laser calibration

A properly aligned laser can reduce the risk of inaccuracies while laser cutting. So, a periodic laser calibration checks are important for high-precision cutting and reducing material loss during the cutting process.

10. Regular oil lubrication of its moving parts

Some laser cutting heads have moving parts, such as focusing mechanisms. Apply appropriate lubricants to these parts to prevent wear and maintain smooth operation.

11. Machine’s functionality check-ups

the machine’s components needs a regular cleaning and calibration work. And the maintenance work by performing a start check-up with its laser head and the machine calibration.

Watch the video

Watch the video for the better clarity over the performance of laser cutting head.