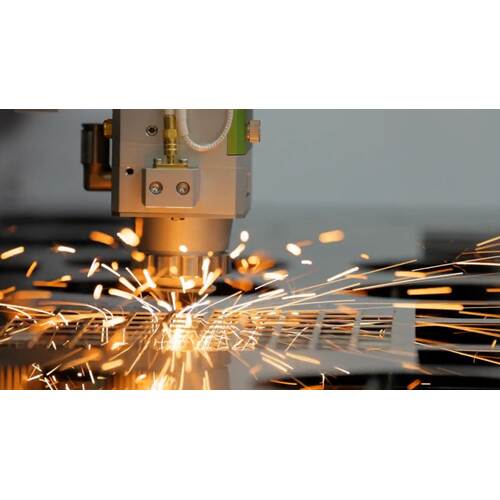

A laser cutting machine is fully automatic and laser cuts the metal surface through optic fiber laser beams. Hindcam is in the manufacturing of various laser powers of laser cutting machinery with high-tech features. That includes 1 kW onwards, and it leaves high-precision laser cuts, engraving, and CNC designs. So, this is effectively contributing to many industrial applications in metal fabrication, heavy tools and machinery, automobile parts/components, and so on.

Main laser cutting machine applications

Laser cutting machines contribute to high-precision cutting and automated complex designing with their CYPCUT2000 upgraded software. Here are the various industries that successfully implement this technology, which saves cost and time and gives fast industrial growth. Here are some core key applications:

1. Metal Fabrication Industry:

In the metal fabrication business, the different metal materials are SS, MS, aluminum , brass, and copper with heavy sheets. This laser cutter can very efficiently cut the sheets into different shapes and designs. Hence, it is thoroughly used in many industries for their metal parts/accessories making.

In the metal sheet industry, high precision and error-free cutting matter alot and give accuracy and high-end cutting results to job works businesses. The industrial parts that we make via a high-powered laser cutting machine. Includes brackets, facade designing, grill/gates designs cutting, mounting plates, SS frames, hoppers, and chutes, SS containers, and many others.

2. Prototyping-making Industries

A prototyping industry is a fast-growing industry, as prototypes are needed for almost every industry. A laser cutter has CNC software that makes designing the ideal and precise prototypes for the machines and their parts. And it is widely used in industries like automobiles, aerospace, medical tools, and electronics components.

3. Biomedical instruments and tool-making industries

For the metallic equipment fabrication used in the medical field. High-end cutting and designing are applied through the advanced features of CNC software. It helps in creating high-precision designs and implementing them through the laser beams over the varieties of biomedical device manufacturing. It includes stents, catheters, micro-needles, microscopic devices , surgical devices used in OT, care devices, etc.

Read More

4. Aviation and aerospace sectors

Aviation industries are very critical and need ultra-high accuracy with their components. A laser cutting machine consists of a laser cutting head that autofocuses the required cutting parameters. And cut, drill, and engrave the cutting patterns to make their components with no deformation possibilities. The components are made with aluminum, SS, MS materials and can be integrated with its structural and physical components.

main components: Fuselage frames and bulkheads, Wing ribs and spar webs, Engine brackets and mounts, Custom brackets, covers, and tooling fixtures.

5. Hardware manufacturing industries

A laser cutting machine gives high-precision, accurate, fast laser cuts over the material upto the required thickness level to make the hardware products. And this industry can make the products faster than the conventional techniques. It includes wrench, drilling tools, nuts, screws, bolts, metal gears, nuts, clamps, studs, and much more.

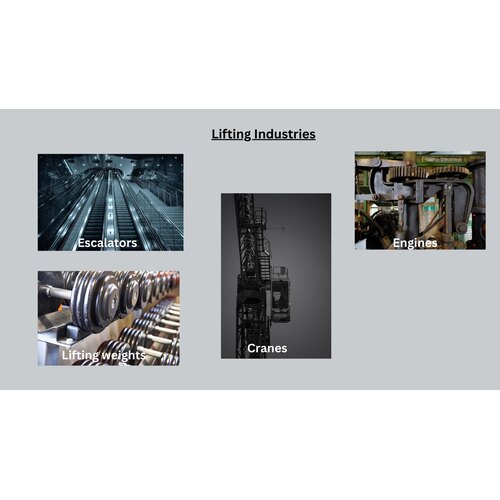

6. Lifting and elevator equipment industries

Laser cutting machines make the important components associated with lifting and elevator systems. And it plays a critical role by providing high-end cutting, engraving, and required designing works implementation with precision, safety, and durability all together.

Its components include forklifts, hoists, and gantries, connector plates, cranes parts, elevators, mounting motors, sensors, and pulleys and much more.

The laser cutting process is widely used across industries, offering high precision, high speed, and cost-effective and sturdy parts/components making. It enables the efficient production of complex, high-quality components with minimal waste. From prototyping to aerospace to elevator making, highly automated laser cutting machines ensure safety, durability, and design flexibility with their CNC-based software commands.