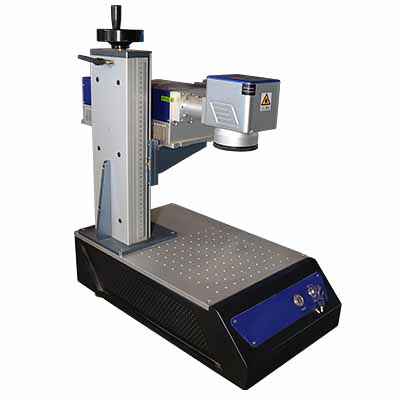

Hindcam Pvt. Ltd. is a well-known brand for the UV laser marking machine it supplies and manufactures on a large scale. A 3W laser marking machine is highly efficient in taking over high-precision marking work using UV laser beam emissions. It is perfect for marking and engraving metallic and non-metallic materials like stainless steel, aluminum, wood, plastics, leather, etc.

Machine’s Specifications

- Laser Power-3W

- Marking Speed Capacity-8000 mm/s

- Automation Grade-Automatic

- Voltage-210 V

- Frequency-50 Hz

- Phase-Single Phase

- Laser Power Stability- +/- 3%

- Starting Price: Rs. 360000 +18%GST

- Call/Whatsapp: 9212300300

Features

- Excellent Beam quality: The machine has a smaller spot beam size, which makes the beam emission sharper and of fine quality.

- Less heat-affected zones: During the marking operations, the heat-affected zones are lesser, which makes the laser marking quality deformity-less.

- Highly efficient: For getting highly efficient laser marking you can use a 3W-laser marking machine.

- Cooling System: It is an air-cooled laser system, that self-adjusts the heat effects.

- Lower power consumption: Machine performance is stable and consumes low power, so always profitable for cost reductions.

Applications

- 2-dimensional markings: A 3W laser marking machine, is helpful in precise laser marking of two-dimensional marking like bar codes, serial codes, text patterns, etc.

- Glassware surface perforation: For glassware art and gallery works, surface perforation helps in the design. So, a laser machine helps in laser markings and engravings on its smooth surfaces.

- LCD liquid crystal marking: For the LCD screen two-dimensional code marking, UV lasers are quite efficient.

- Electronic tools and components: Electronic items are very sensitive and have intricate designs, so it needs very precise and focused markings. It includes transistors, resistors, capacitors, diodes, and amplifiers, for music systems, TV panels, etc.

- Jwelery markings: For precise jewelry markings and designing, a UV laser marking machine does precision work. It includes Gold, silver rings, bracelets, earrings, etc.

- Leather designings: By using 3W laser markers, you can easily engrave and design beautiful patterns over leather jackets, bags, wallets, shoes, and many others.

Know more here: Application of UV Laser Marking Machine

Advantages

A UV laser machine can always be advantageous for many industrial applications. So, here we shall be discussing all those in brief:

- Non-contact process: The entire laser marking process of a UV laser marking machine is non-contact.

- High-precision and fine marking quality: The marking quality over the specified marking area of material surfaces is extremely focussed, permanent, and of higher quality. In addition, a 3KW laser marking machine can do high-precision marking via the UV laser beam emissions.

- Minimal maintenance required: A laser marking machine can work very efficiently for many years, with very less maintenance.

- Easy customizations using software: The machine’s software easily helps in easy customizations of the marking requirements, like depth control, marking designs, lens adjustments, etc.

Read More

Disadvantages

- 2D-marking: For the designing works, marking quality, and any other operations, there are axis-dimensional limitations.

- Material-depth limitations: The UV lasers have limitations over the material thickness. So, fine marking is only possible up to a certain depth.

Samples-3W UV Laser Marking

Frequently Asked Questions

Q1. What is the current price of a 3W laser marking machine?

Answer: A 3W laser marking machine has a current price of Rs. 300000 +GST. Also, for better clarity, you may connect us by Call/Whatsapp: 9212300300. Also know here: Laser marking machine price.

Q2. What should we look for before choosing the right UV laser marking machine?

Answer: Although, choosing the right laser marking machine depends on usability preferences. However, before the purchases, we must ensure certain factors. It includes marking area, marking speed, material compatibility, upgraded software, and many others.